Heat Loss from Residential Uninsulated main steam piping

Contrary to belief, it is important to have the main steam pipes in the basement insulated. If the piping is uninsulated, those pipes will become the largest radiator in the system. If the uninsulated main piping was calculated when the boiler was sized, it will work OK, but at a higher fuel cost.

If the bare piping was not included in the original sale of the replacement boiler, you may not be able to heat the home, or it may cost more.

The bottom line is, if the main piping in the basement or crawl space is not insulated, insulate it.

Before I get into how much you are losing, let's look at the result of operating a steam system with uninsulated steam mains.

1. Creates more system noise due to excess water in the steam main.

2. Slows down the heating of the home because the steam keeps turning back to condensate.

3. May cause the boiler to flood the system with water, and an automatic water feeder. As the condensate in the steam main is actually water that should be in the boiler and is now in the main, the water level in the boiler could drop low enough to trigger the feeder to feed more water. When the condensate finally returns to the boiler, excess water can remain, affecting steaming.

4. Increase fuel consumption

5. Higher boiler installation costs - If the uninsulated main was figured in, it may push the contractor to bid a larger boiler size, which will cost you more money in the Proposal price.

Insulating the main piping

Here is what this pipe insulation looks like, and shows the tape pulled back

How much fuel does insulating the main save?

In all honesty, I don't know because there are too many variables.

1. How long is the boiler off between cycles?

2. How cold is the basement or crawl space surrounding air temperature?

3. What size is the pipe?

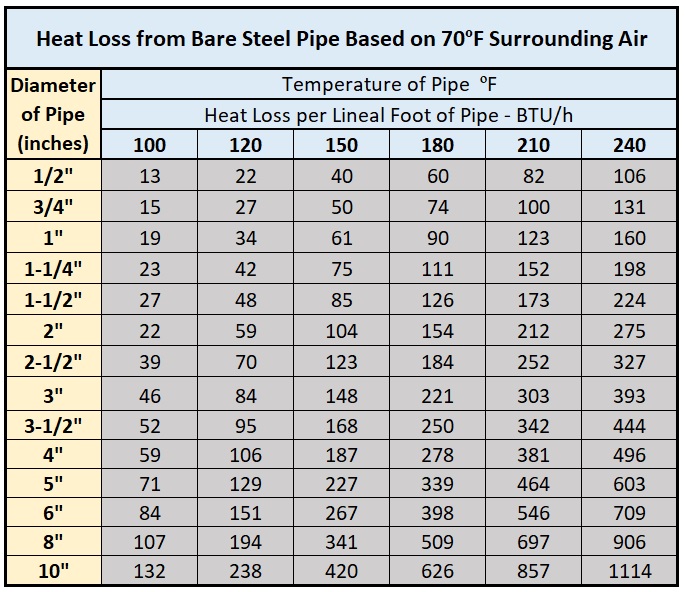

Below is a chart that shows a surrounding air temperature of 70F. The steam pipe temperature is 210°F, but in reality, it is closer to 215°F. It's not rocket science, but if you like, there are online loss calculators for an accurate number.

The chart shows that a 2" iron pipe loses 212 BTUs per linear foot. Let's assume you have 120 feet of 2" iron pipe. This includes near boiler piping and all vertical and horizontal pipes in the basement from the boiler to the end of the steam main. Do not include the return piping. That is 25,440 BTUs per lineal ft per hour. Think about this: the different BTU content of equal measurements per hour of natural gas (100,000 BTUs), Propane (LP) (76,000 BTUs), and fuel oil (138,000 BTUs). For every hour we produce steam, we lose about one-quarter of the natural gas input and a third of a gallon of propane. If the surrounding air temperature is below 70F, I would say most unfinished basements are closer to 55F-60F, especially depending on your location and outdoor air temperature. You can see other BTU losses for different pipe sizes.

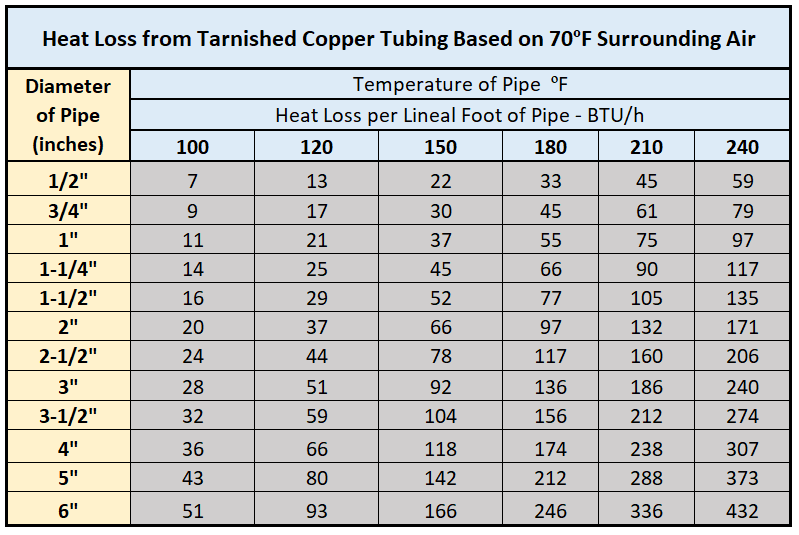

Steam-carrying pipes should be iron, not copper, but there is also a chart for copper pipe loss per linear foot.

Disclaimer: The information found on this website is for informational purposes only. All preventive maintenance, service, and installations should be reviewed on a per-job basis. Any work on your heating system should be performed only by qualified, experienced personnel. Comfort-Calc or its personnel accepts no responsibility for improper information, application, damage to property, or bodily injury resulting from the application of information found on this website, as a professional should review it.