Buffer Tank Flows

The use of buffer tanks adds water volume to the heating system. The flow through the tank changes. The boiler side of the flow in the tank can be either constant or variable, depending on the type of boiler circulator used.

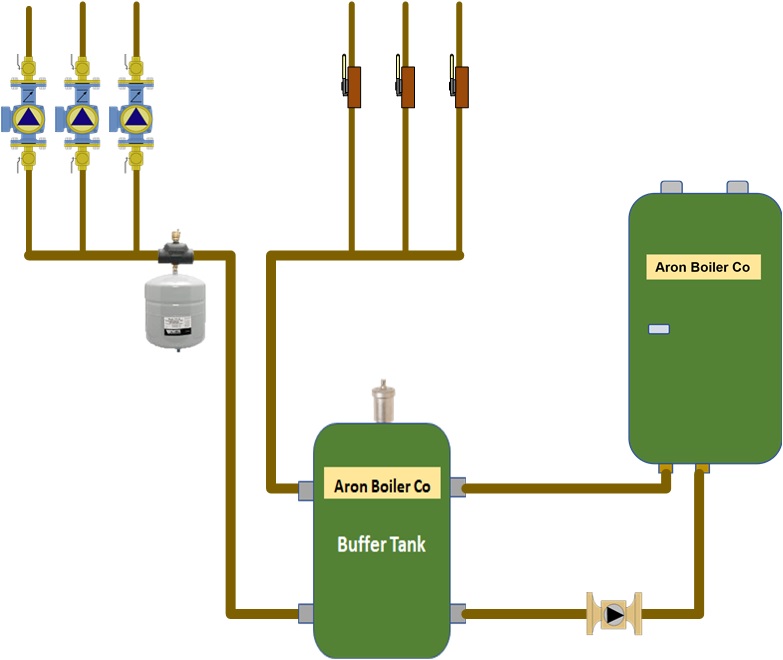

Below is a normal piping strategy to add a buffer tank to a high-efficiency or cast-iron boiler.

- Oversized boiler

- Micro-zoning

- Zones different heat temperature so not to use mix valve

- Hydraulic separation

A buffer tank will hydraulically separate the boiler flow from the system flow, as these could be much different. Normally, the flow through the boiler is consistent, and the system flow is variable. Let's examine how the flow in the tank changes as the system flow changes.

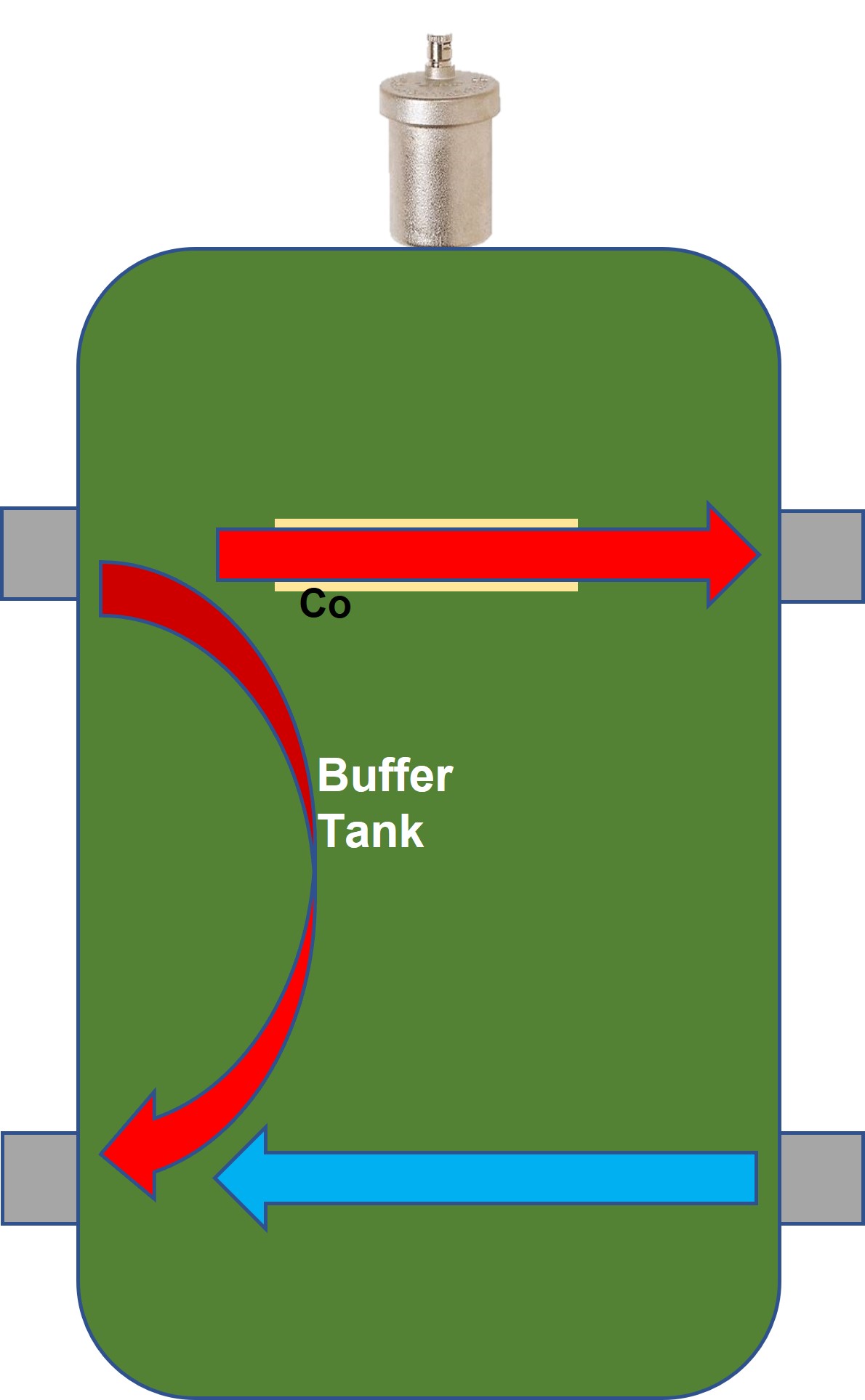

Boiler flow is greater than system flow

This happens when a small zone is operating that would have less flow than what is required by the boiler. The boiler would likely short-cycle, resulting in lower efficiency and increased fuel consumption.

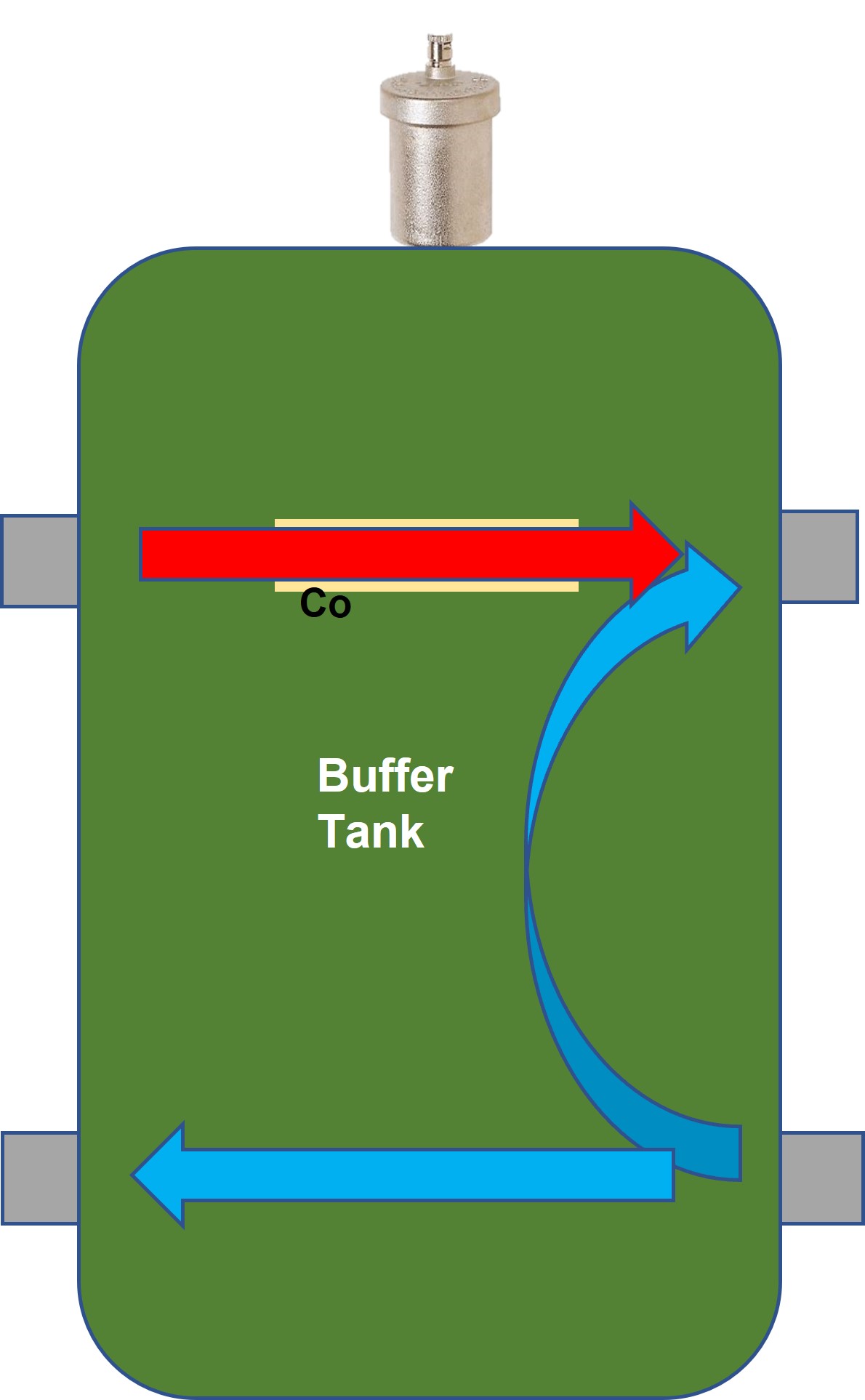

System flow is greater than boiler flow

The system flow is greater than the water flow required by the boiler. The only downside here is the temperature of the water going to the system. This may or may not satisfy the thermostat.

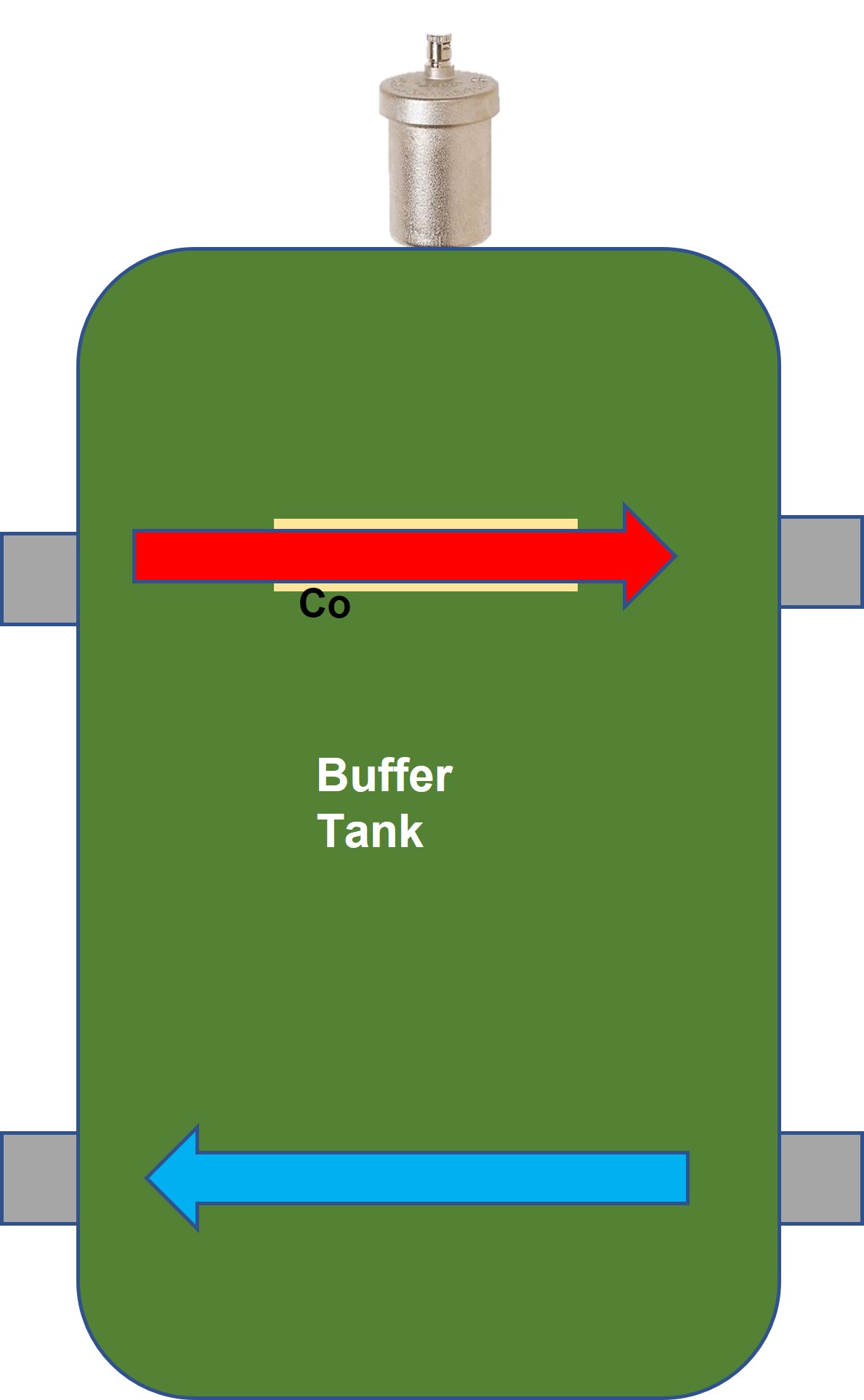

Equal flow through the system and boiler

This is a good situation, the flow through the boiler is matching the flow required by the system. The boiler will continue to run until the heat demand is satisfied.

Disclaimer: The information found on this website is for informational purposes only. All preventive maintenance, service, and installations should be reviewed on a per-job basis. Any work performed on your heating system should be performed by qualified and experienced personnel only. Comfort-Calc and its personnel accept no responsibility for improper information, application, damage to property, or bodily injury from applied information found on this website.