Ask Your Boiler and System Questions or Leave Your Comments Here

Avoiding air problems

Air elimination through the last couple of decades has changed dramatically. Four or more decades ago, the circulator(s) were located on the return piping of the boiler, and air elimination was achieved using a B&G Airtrol fitting, pictured below, mounted on the supply pipe with a dip tube extending into the boiler. The dip tube was positioned low enough in the boiler that no air entered the supply piping. There was a bell-shaped fitting that the dip tube emerged from, which collected the air and led to a ceiling-mounted expansion tank. Purge valves were installed for zone purging of air when the boiler was installed or if the system needed to be drained for service. This application worked very well.

As the boiler industry evolved, we did away with air control fittings with dip tubes and added automatic air vents and air separators. We still added purge valves for purging the air pond boiler installation or system service. At this point, people began adding automatic air vents with non-diaphragm-type expansion tanks. This created a problem of having a non-maintenance style tank, to a tank that needed draining.

As we continue to move forward with air elimination from hydronic systems, about 1958, the manufacturer suggested moving the circulator from the return side to the supply side of the system. The reason for this is credited to the introduction of a one-piece circulator. Before the one-piece circulator, we had three-piece circulators. The three-piece circulators could move much more water for their size than the one-piece circulator.

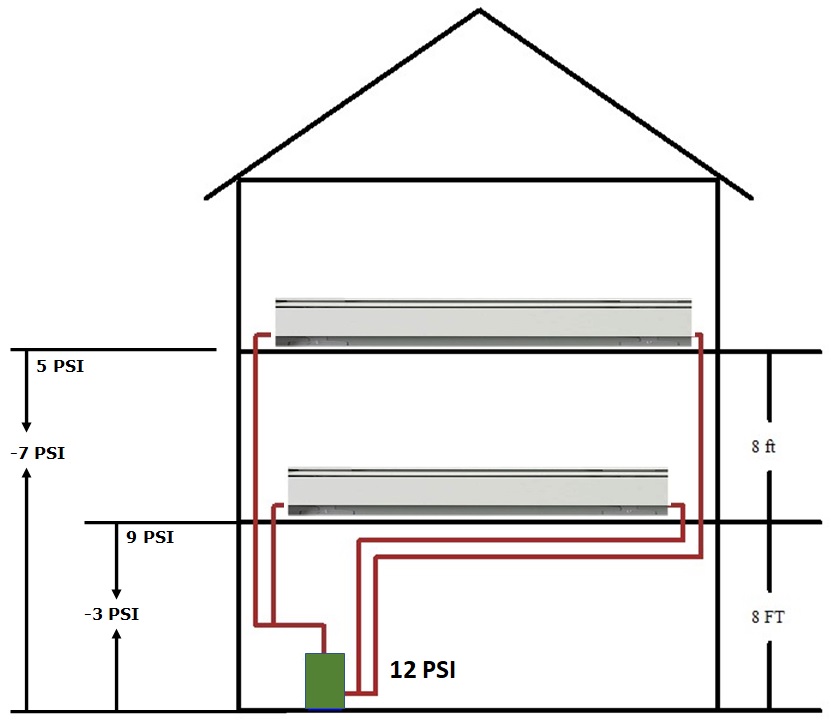

Let's look at a drawing when the circulator is not running. If there is no pump operation, water pressure would be the same at any given altitude in the system. For instance, if we measure four feet from the floor and the water pressure is 14 PSI, any of the system piping located four feet off the floor would have a pressure of 14 PSI. If we measure 15 feet off the floor, and the pressure at that point would be 6 PSI, any pipe at 15 feet off the floor would be 6 PSI

When a circulator is running, the pressure on the outlet side will always be higher than the pressure on the inlet side of the circulator. The point where the expansion tank is connected to the system is referred to as the point of no pressure change. This means that if the system is filled to 12 PSI, that pressure will remain constant unless we manually adjust the water temperature, fill the system, or drain it. So, if the pressure does not change at the expansion tank connection, the circulator can add system pressure or drop system pressure. The simple rule is that the pressure on the side of the circulator where the expansion tank is located remains unchanged.

If we place the circulator on the return piping or the supply piping so the circulator is pumping towards the expansion tank connection, the pressure is going to remain at the system fill pressure. For instance, if we have a 12 PSI fill pressure on the system, the circulator discharge pressure pumping towards the expansion tank connection will remain at 12 PSI

Circulator installed on return piping

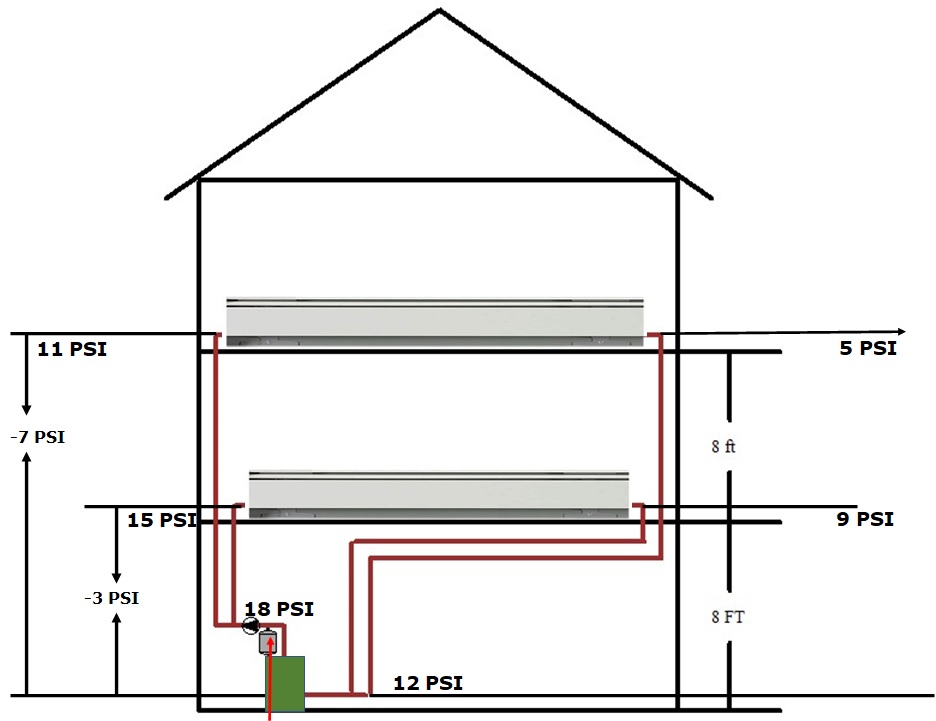

Installing the circulator on the supply pipe after the expansion tank connection means the inlet to the circulator would remain at 12 PSI with a 12 PSI fill pressure, and the discharge pressure would be increased, adding pressure to the system. Depending on the size of the circulator, we could add 50% or more of the system fill pressure.

Automatic Air Vent Information

Automatic air vents were introduced in the mid to late 1950s. This was both a good and a bad idea. The idea was initially good when it was required for the introduction of bladder-style expansion tanks, but it became a bad idea when installed on non-diaphragm, ceiling-mounted steel expansion tanks. You will hear automatic air vents referred to as hy-vents, barrel vents, can vents, and possibly other names I'm not familiar with. I will refer to them as auto vents for short.

You will find auto vents all over the system. I've seen them at the boiler, at the high points of the system, on stamp pipes where the returns and supplies are located in the basement, and inside cabinet convectors and baseboard covers upstairs. I have seen these vents create problems as they leak or spray water over time. I've seen damage to wooden floors, rusting radiation covers, damage to walls, etc.

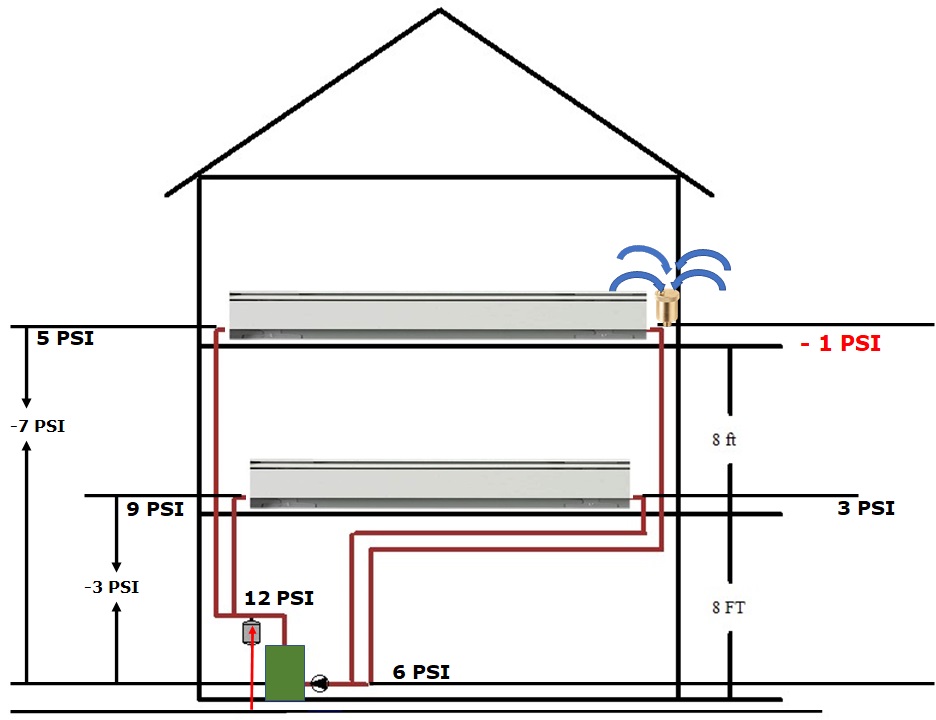

Today, with the use of better air separators and one-piece circulators that can add a little more pressure to the system, fill pressure auto vents anywhere in the system are not required; in fact, they can be detrimental. If a vent can automatically vent air, it can automatically suck air in under other conditions. Let's assume the system pressure is 12 PSI, and the circulator is located on the return side, pumping toward the expansion tank connection. When the circulator starts, it can lower the pressure sufficiently for the high vent to draw air in. After the circulator stops, the air drawn in can be vented back out, but some of the air has mixed with the water and returned to the boiler.

It is best to do all air elimination at the boiler, taking advantage of the extra pressure added by the circulator when pumping away from the expansion tank connection.