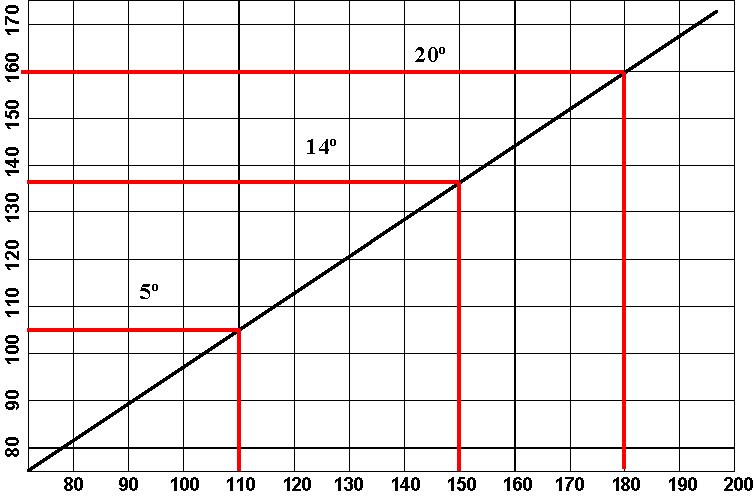

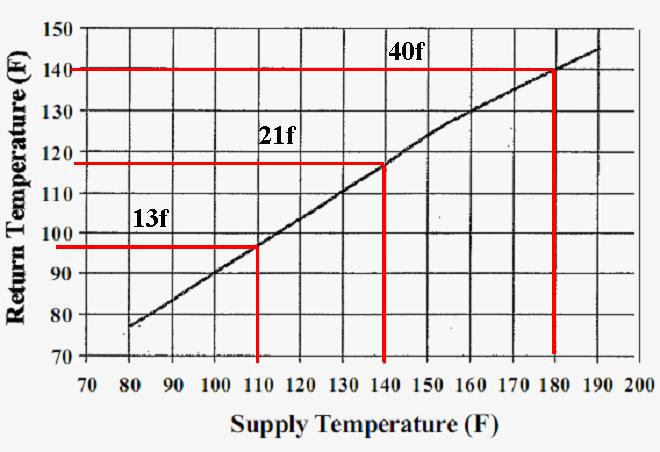

Delta-T Charts

When discussing delta-T, the phrase can mean temperature rise or temperature drop. This term could also refer to changes in boiler or system temperature. The temperature rise in the boiler is primarily influenced by BTU input, thermal transfer, and fluid flow. Manufacturers set the boiler input and delta-T in high-efficiency boilers, and cast-iron boilers typically have a 20F to 40F rise.

System temperature drop is dependent on fluid flow rate, fluid temperature, heat emitter (radiation) construction, amount of installed radiation, and air flow. System delta-T is usually between 15f and 40f, depending on heat emitter type and application. Through non-fan-style emitters, as the flow decreases, the output also decreases. If the flow increases, the emitter output increases. When hot water is passed through a coil and air is passed across it, the BTU output is affected by both the fluid flow and air flow through and around the coil.

Heat emitters vary greatly in style and construction. To name a few, they consist of copper tube/aluminum fin baseboards, steel pipes/steel fins, cast iron radiators and baseboards, radiant tubing, and hydro-air ducts or cabinet coils.

20F Delta-T Chart

40f Delta-T Chart

You can measure delta-T increase or decrease with accurate thermometers. To calculate flow, you would need to use the Hydraulic Formula.