Installing Fuel Oil Tanks

Indoor Tanks

I'll start by saying that as the codes change, you must stay on top of the changes and follow the manufacturer's installation instructions.

Fuel oil tanks commonly are 275-gallon tanks and fit through a standard 30" doorway. For more narrow doorways, tanks are also offered 28" wide and hold 230 gallons. As of the date of this writing, the code allows up to 660 gallons inside on the same level or below the oil-fired appliances. The introduction of 330-gallon tanks was offered to meet the code at least 40 years ago.

The indoor tanks are offered in a vertical or horizontal style. Tanks are available in both indoor and outdoor styles. I will not discuss buried tanks because it is too involved to cover thoroughly.

A single tank installed in the basement is a pretty simple installation. Find a solid base to set the tank near an outside wall with easy access for the oil delivery person to access on the outside.

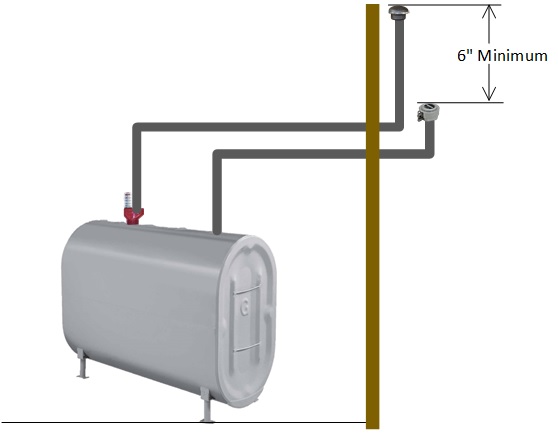

Here is a standard tank installation

- Legs should be 10-1/2" on the valve side of the tank and 12" on the other side of the tank. This prevents any moisture from staying in the tank. 1/4" per ft drop.

- Install tank so welded seam is not against the wall for leak inspection

- Install 5' minimum from the oil burner and 3' from an electrical panel

- Do not use Teflon tape on any of the threads

- Use swing-joints with a downward pitch to the tank

- When installing the vent alarm gauge, make sure the float will not be under the fill pipe, as it may cause damage to the float assembly.

- Pipe with iron pipe, 2" minimum of the fill pipe, and vent pipe is normally 1-1/4" but should be 1-1/2" or 2" minimum

- Fill pipe outside should be 5' from any gas appliance outlet and combustion air inlet

- 3 feet from any building air inlet

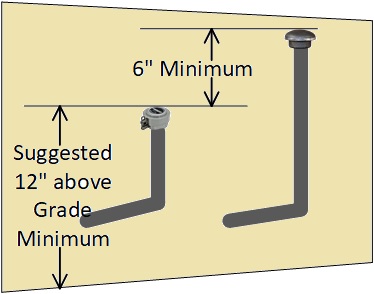

- Fill pipe should be a minimum of 12" above grade when exiting building and vertically a minimum of 6" higher to termination

- Tank vent pipe termination should be a minimum of 6" higher than the fill pipe termination's

- Fill pipe and vent pipe should have screw on caps even though they offer slip-on caps. Vent cap should have a bug screen in it

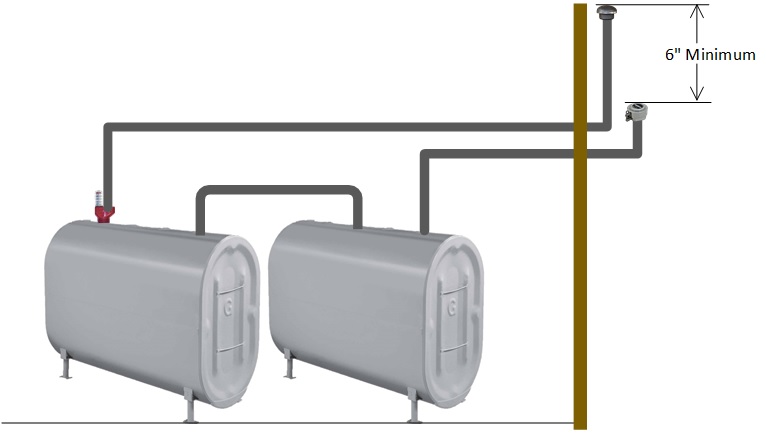

Dual Indoor Tanks

- Crossover piping from tank-to-tank use 2" iron pipe

- The use of a ground union will be needed

- Fill the first tank and vent the second tank, no need to use gauges

- Does not matter which opening you use, but be aware of the crossover pipe flow and float assembly of the vent alarm gauge

Outside Oil Tanks

- Minimum of 5 feet from property line

- Avoid falling ice and dripping water on tank

- Make sure the tank is on a solid base. You can use floor flanges for more support

- Outside tanks =normally the use of a surface draw kit is used

- Tank legs of 10-1/2" to 12" slope towards the drain valve or plug.

- Insulate oil lines

- Most of the time, the fill pipe is a 2" x 6" nipple with a cap screwed on the top of the nipple.

- Vent pipe is still a good practice to be 6" higher than the fill pipe termination

- When installing the vent alarm gauge, make sure the float will not be under the fill pipe, as it may cause damage to the float assembly.

Fuel Oil Line Indoors

The fuel oil line must be protected when in contact with concrete. I do not recommend installing the oil line in concrete.

Oil lines may run on the floor or overhead. If the line is overhead, attach it to the floor joists, but use soundproofing between the oil line and the floor joists to minimize the risk of hearing the fuel oil pump vibration upstairs.

When the lines are run overhead, it may be a bit problematic at times after changing the fuel filter. There are three different ways to handle this problem. Number one is the best application.

Option 1. Install a Tiger Loop at the oil burner. The Tiger Loop will use a single line from the tank and utilize a 2-pipe oil system at the oil burner. This will increase the amount of vacuum the pump can produce, and the Tiger loop also has a built-in deaerator.

Option 2. Install a two-pipe system. This would be a supply from the tank and return pipe to the tank. This could be a bit noisier operation.

Option 3. Install the fuel filter at the oil burner, and above the filter, install a shut-off valve. After changing the fuel filter and reactivating the pump, open the pump bleeder and allow the burner to run for approximately 30 seconds. With the bleeder still open, open the shut-off valve in the oil line. The vacuum produced in the filler prevents air from entering the oil line, thereby preventing shutdowns and the need for bleeding.

I am a firm believer that when coming off the bottom of the oil tank, having an empty fuel filter bowl at the oil tank, install an oil filter at the oil burner. The reason for this is that the empty filter tank at the oil tank is used as a sump. The oil moves relatively slowly through the oil lines. This allows any dirt or moisture to drop into the sump. It should be checked every few years for dirt or water build-up.

While many steel fuel oil tanks are still being used, the Roth double-wall tanks are becoming very popular in many areas. I have never used one, so I cannot speak about them. I would welcome any positive information that anyone can provide to be added to this section.