Hot Water Boiler purge Options

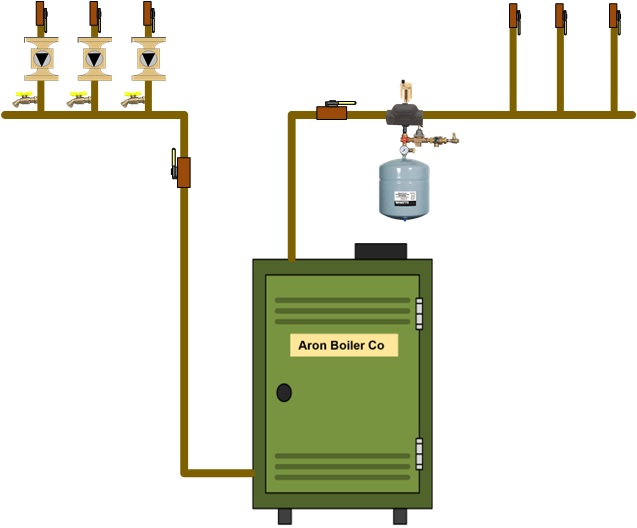

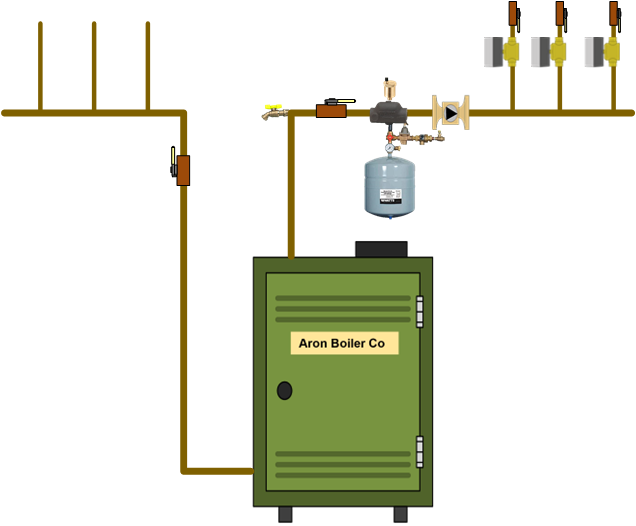

After draining the boiler for servicing or installing a new boiler it will need to be refilled and purged. There are many ways this process is piped in dependent on the contractor's general practices, age of the existing system, type of system, or parts available at the time.

1. System must be purged with hot water - False, it does not matter cold or hot

2. System must be purged with cold water - False, it does not matter cold or hot

3. System must be purged with the water flow the same as it flows when heating - False, it does not matter direction of flow

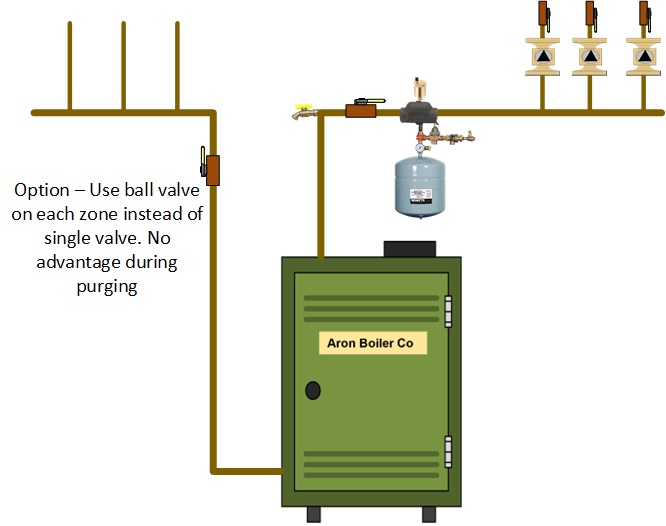

4. Each return pipe needs it own purge set-up - False, fittings can be saved looking at optional piping practices

5. It is best to put the end of the hose used for purging in a bucket to verify you always get all the air out - This is not needed but not bad either. The problem is you can never get all the air out by purging the system. There is oxygen in the water you are purging with. After purging to eliminate the rest of the air the water should be heated and flow through an air eliminator

6. Systems should be purged every year - Nope, if piped properly the initial purge should be all that's required. The rest of the air the boiler and components can remove if all components are in the proper location.

A newer way of setting up purge stations is to install a drain on the boiler supply, shut-off valve, and ball valves on all returns. While the return ball valves are optional, it allows for zone isolation. There is no longer a need to move the hose from drain to drain on the separate zones. Another advantage id if the components are placed in the correct places you can isolate the supply to service the PRV, backflow preventer, air separator, vent if used, circulator(s) flow checks or zone valves without having to purge the system if refilling is done properly. This only means one at a time, open valve above the closest circulator to the air separator. Turn on the circulator. You will hear the air coming back and venting, move to the next, then the next until done. You will not have enough air to stop flow so the boiler will remove the small amounts per zone.

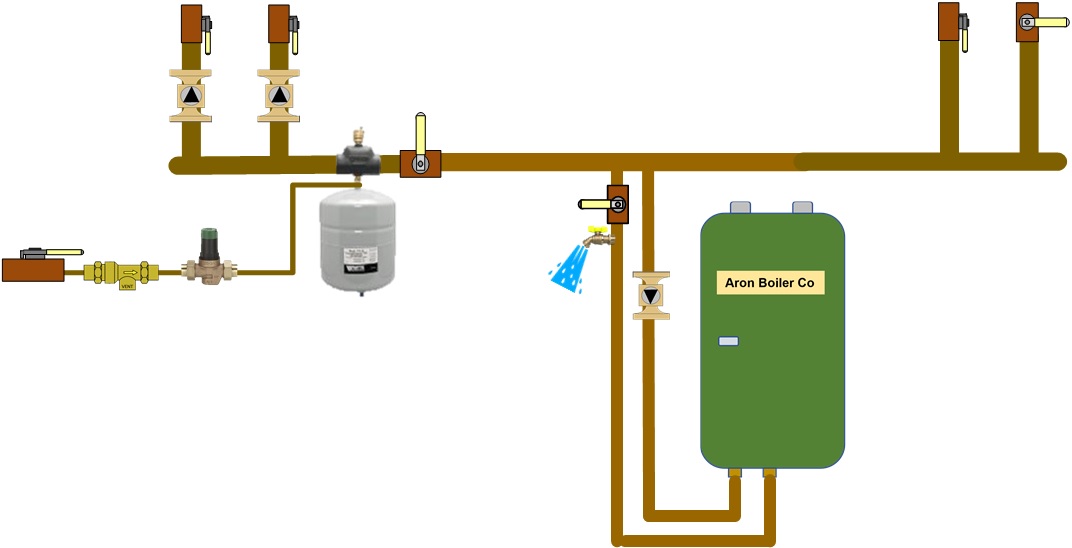

Lastly many boilers today are piped primary/secondary piping. I feel the best way is to put the purge valve and drain on the boiler piping. All the zones and boiler may be purged through a single drain.

To purge you close the valve above the drain and all the zone ball valves. Open the drain and open a single zone at a time until all zones are purged. Open the valve on the boiler supply to bring water in from the feed to purge the last little bit of pipe.

Disclaimer: The information found on this web site is for informational purposes only. All preventive maintenance, service, installations should be reviewed on a per job situation. Any work performed on your heating system should be performed by qualified and experienced personnel only. Comfort-Calc or its personnel accepts no responsibility for improper information or application, damage to property or bodily injury from applied information found on this web site.