Skimming a Steam Boiler

Why a steam boiler surges

When a steam boiler is installed, there is an oil residue from the manufacturing, oils on the iron pipe, oils from cutting and threading the black iron pipe, and possible oil from fluxes and thread sealant.

All steam-carrying pipes should be iron pipes, and the piping below the water line of the boiler can be iron or copper. The reason for this is twofold. When copper steam-carrying pipes are used, this allows the steam to leach copper molecules from the copper tubing. The copper molecules will eventually return to the boiler, setting up a galvanic reaction that may shorten the boiler's lifespan. The second reason is that the expansion rate is significant, and all copper joints are brazed or silver soldered, which eliminates any play or movement. The near-boiler piping requires swing joints, which absorb expansion by rotating slightly when heated and cooled, and cannot be implemented without threaded fittings.

The water is then put in the boiler, and the switch is turned on. As the water continues to heat up, the oil will gradually float to the water's surface. The oil slick slows down the escape of steam into the boiler steam chest and piping. The tiny steam bubbles will join forces and become larger and larger. When the steam bubble gets large enough to break through the oil, it will be moving at a higher velocity. Once a hole is blown through the oil slick, all created steam bubbles will take the path of least resistance and use the same hole. The steam moving at a higher velocity reaches the boiler supply tapping and begins to squeeze into the openings, increasing its velocity even further.

Now we start producing a venturi effect as the steam rushes to a lower pressure zone, the system piping sucks water from the boiler up into the pipe with it. The water level in the sight glass starts to drop. Most of the water is too heavy to continue up the pipe and drops back into the boiler. The water level in the sight glass goes up. We now have wet steam, which moves more slowly and releases its latent heat much more quickly, causing the steam to turn into condensate. This water must return to the boiler, reheated, and turned back into steam. The boiler must use 970 BTUs to recreate this steam.

The water leaving and dropping back into the boiler is called surging and can cause the water level to bounce up and down more than about 1/2".

When the water bounces an inch or more, it is considered severe surging. Some of the water seeps into the system and runs down the main pipe, condensing steam into water along the way. If there is enough water in the boiler, an automatic water feeder will add more water. When all this condensate and added water return to the boiler, it is now overfilled or flooded.

When the water level in the gauge glass bounces more than 1/2" or the water level drops to the bottom of the glass or even disappears completely while steaming, the boiler needs to be skimmed.

Option 1

- 2 - Buckets, at least one being a 5-gallon bucket

- 1 - Pipe nipple at least 6" long

- 1 - Ball valve the same size as the pipe nipple, optional.

- Turn off the boiler

- Carefully open the boiler relief valve to verify there is no steam pressure in the boiler

- Find and close the manual fill valve

- Find the skim taping plug, and safely remove the plug from the boiler.

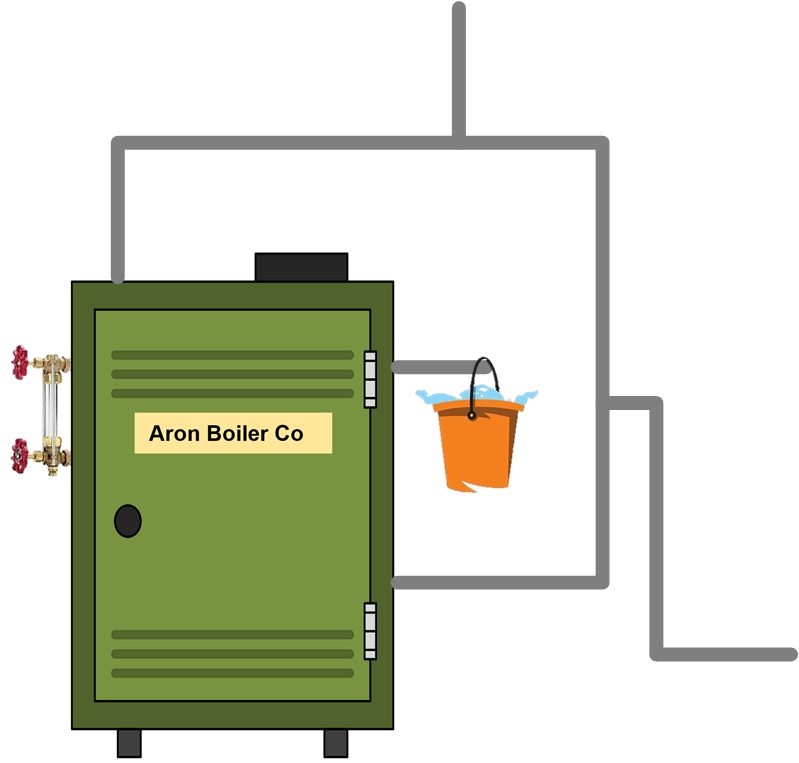

- Install a nipple with a valve into the boiler tapping. This pipe nipple must be horizontal. It must come straight out. It cannot go uphill or elbow up. We are trying to skim the water surface, so the water must come out of a horizontal pipe

- Turn on the boiler and run the boiler until it gets hot but does not make steam

- Turn the boiler off

- Slowly open the valve you installed, making sure you are not in front of the pipe in case there is steam pressure in the boiler. Stand off to the side

- There should not be water at this level

- Open the fill valve slowly until the water starts to flow out of the pipe nipple you are using for skimming. The water will fill quickly, but it is too fast for a skim to be effective. Closing the valve will allow the water to drain down to the skim pipe tapping

- When the water stops flowing from the pipe nipple, re-open the manual fill valve slightly so the stream of water coming from the pipe nipple is no larger than a wooden pencil. The slower the better

- Continue to skim until the bucket is almost full. Remove the full bucket and use the second bucket while you dump the first bucket. Do not close the valve if one is installed, do not stop the skimming process

- Do not re-fire the boiler during the skimming process. This will cause the oils to mix back into the boiler water

- Continue this process until the water coming out of the skim tapping is cool enough to hold your hand under the water flow comfortably.

- When done, close manual water feed, remove pipe nipple and valve, reinstall plug, and drain water to proper fill level. Turn the boiler back on

Skimming the steam boiler from skim taping

Option 2

Skimming the boiler from the header

When skimming is complete, remove nipple and valve and install a plug or cap on the nipple

Disclaimer: The information found on this website is for informational purposes only. All preventive maintenance, service, and installations should be reviewed on a per-job basis. Any work performed on your heating system should be performed by qualified and experienced personnel only. Comfort-Calc or its personnel accepts no responsibility for any improper information, application, damage to property, or bodily injury resulting from the application of information found on this website, as a professional should review it.