Steam Boiler Automatic Water Feeder's

There are many different types of automatic water feeders available today. The various types include electric, electronic, and mechanical. There are also different feed rates for these products; some feed as low as one gpm, and some much faster. Automatic water feeders are designed for residential, commercial, and mixed-use applications. When selecting an automatic water feeder, it is crucial to pair it with the correct Low Water Cut Off (LWCO). For example, you would match an electronic feeder with an electronic LWCO and an electric feeder with a float type LWCO and mechanical feeders to a float type LWCO

There are automatic water feeders like the Hydrolevel VXT-120v or VXT-24v that you can program to set to feed the proper amount of water to get back to the NWL. Residentially, I prefer these over the other types if the owner cannot access the basement to check the water level. The water level will still drop below the best operation level. Still, when the LWCO activates the automatic water feeder, it will feed water until the manufacturer's NWL is met if that is where you have it programmed

.

This is normally done by adjusting dip switches. Another feature that distinguishes the Hydrolevel auto feeder from the others is an electronic water meter. This is important on newer steam boilers, and most manufacturers do suggest adding a water meter to the residential steam boiler feed system.

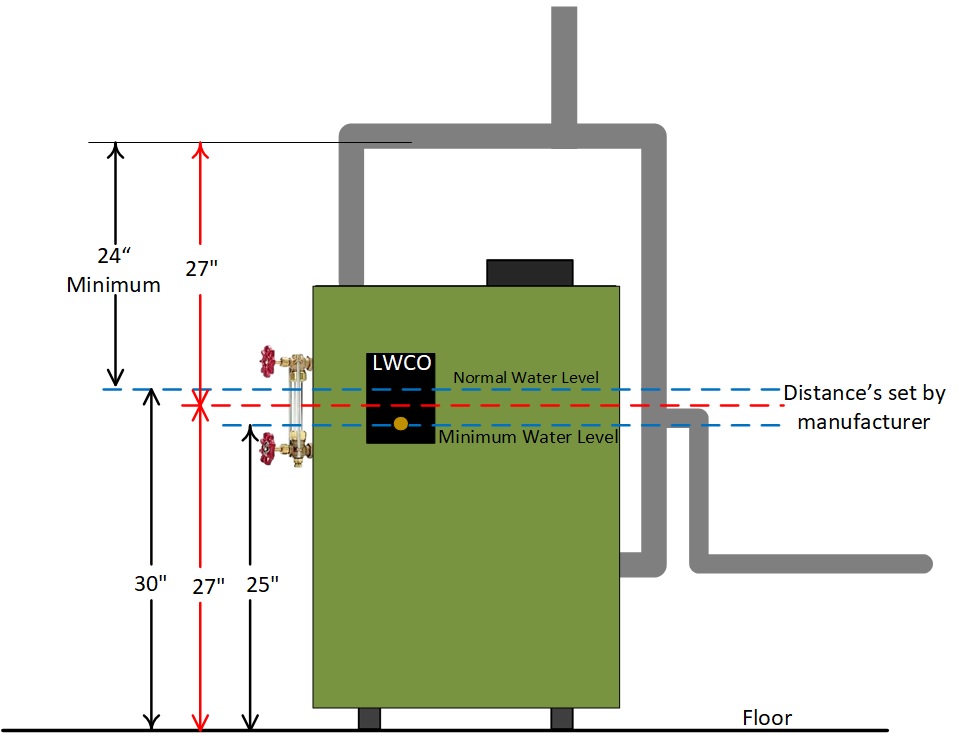

If you're told you do not have to check the water level on a steam boiler, here is the problem. Most LWCOs call for water when the water level drops below the probe on the LWCO. The LWCO will activate the feeder and add water until the water covers the LWCO probe. The auto-feeder will shut off the water flow to the boiler. The Hydrolevel LWCO will operate the same way unless you move the dip switches. The feeder can be set to bring the water level close to the NWL specified by the manufacturers. Following the directions on the auto feeder, the LWCO dip switch would be turned off, and the flow would be set in minutes. They explain clearly how to set the dip switches in the control installation directions.

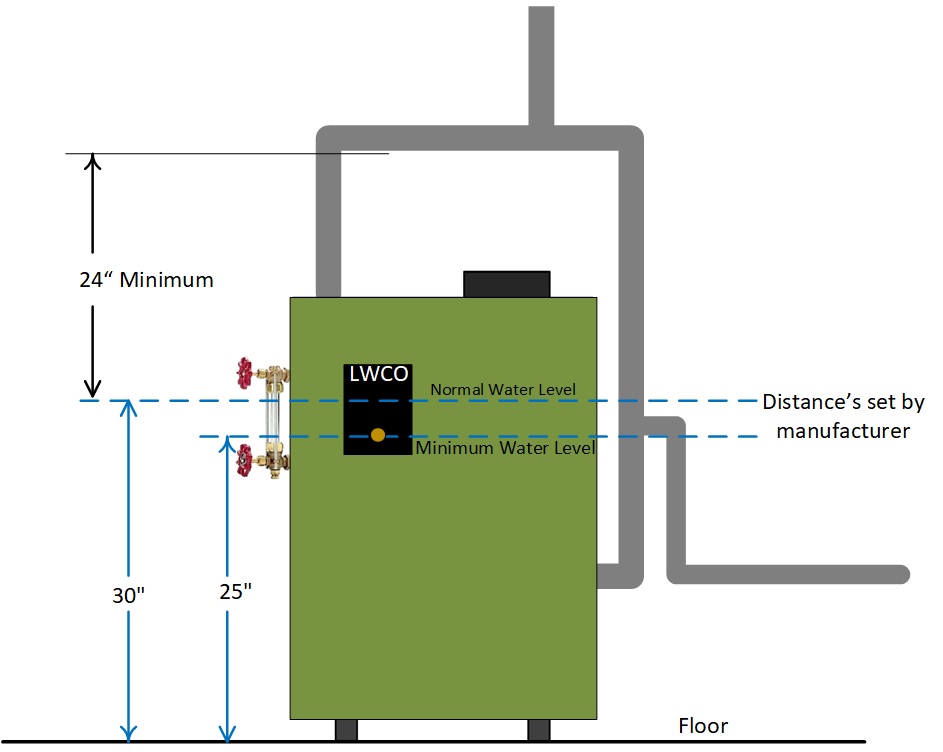

Why is this so important? When a steam boiler is installed, the manufacturer specifies the NWL, which is a good place for steam production. The Hartford loop is to be piped 2" below the Normal water level. The Minimum distance from the NWL to the boiler header is 24". If the NWL is not maintained and left to operate at the probe location, those measurements will now be incorrect.

This is a fictitious boiler, so the levels may not be accurate for your specific product, for illustration purposes only. Maintaining incorrect water levels can affect boiler steaming and shorten boiler life due to the amount of superheated iron above the incorrect water line.