Counterflow Steam Systems

In a counterflow steam system, the supply main is pitched upwards as it moves away from the boiler. This arrangement causes the steam and condensate to flow in opposite directions within the supply main. Here are some key points about counterflow systems:

1. In a counterflow system, the steam and condensate in the bottom of the steam main flow in opposite directions, meaning they are counterflowing.

2. The steam travels away from the boiler, while the condensate flows back toward the boiler.

3. The main supply pipe slopes upward as it extends away from the boiler.

Piping Characteristics:

1. Counterflow systems require larger pipes due to the opposing flow of steam and condensate.2. The pitch of the counterflow main must be carefully designed to accommodate both the steam and the returning condensate.

Distinguishing Features:

1. Look for a drip pipe at the beginning of the main near the boiler. This drip pipe is a characteristic of counterflow systems.

2. If the system main is connected to the boiler and runs out without having a pipe at the end that returns, it is likely a counterflow system.

3. Conversely, if the main turns back toward the boiler with a smaller pipe at the end, it is a parallel flow system where steam and condensate run in the same direction.

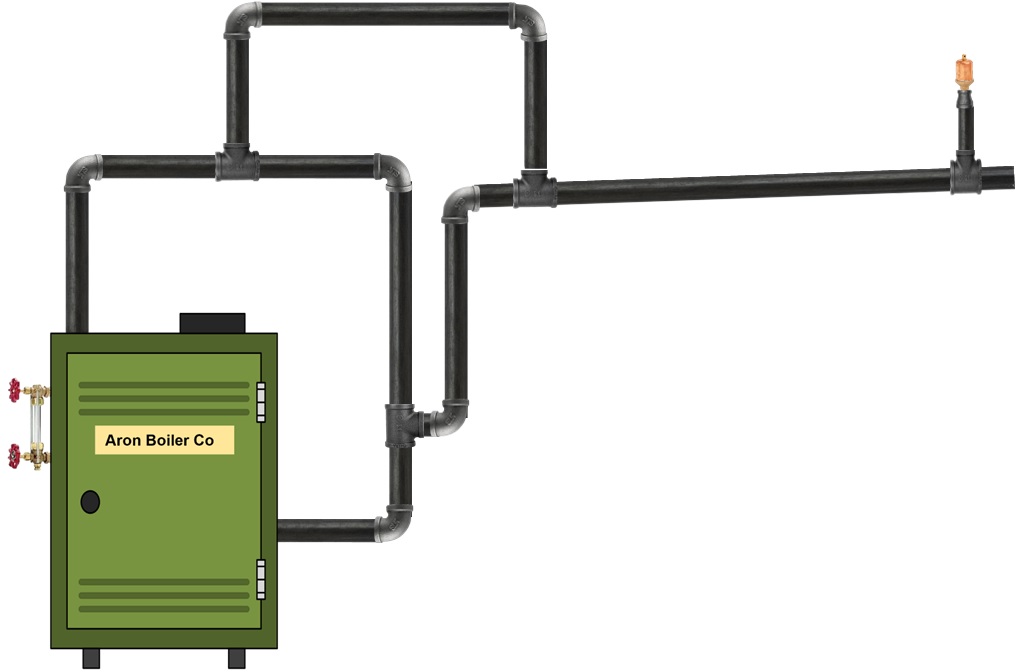

There are a few points to keep in mind when piping in a counterflow system to a steam boiler. As shown in the diagram above, the lowest point in the piping is at the boiler. There will be no return piping from the other end of the basement or from the end of the steam main. It is crucial to pipe the steam boiler riser to the top of the counterflow system pipe. This allows a significant amount of condensate to drain back into the boiler riser, dripping through the boiler's steam chest. If this happens, it will reduce the amount of steam in the boiler by cooling it, causing it to condense. The drip for the counterflow system should originate from the end of the main near the boiler, allowing the condensate to return to the boiler.

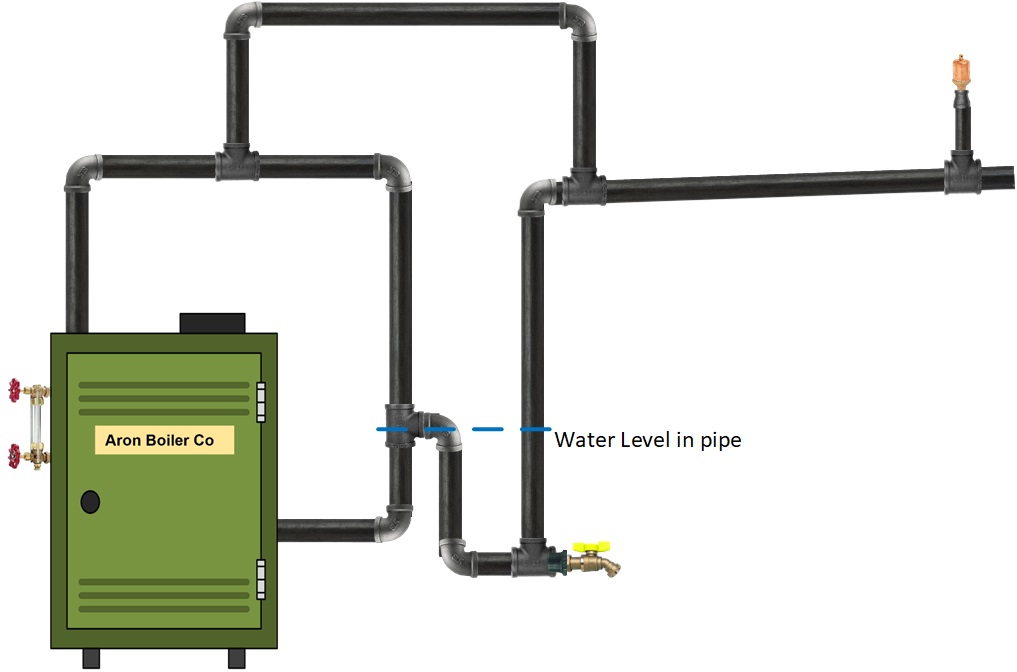

There are a few points to keep in mind when piping in a counterflow system to a steam boiler. As shown in the diagram above, the lowest point in the piping is at the boiler. There will be no return piping from the other end of the basement or from the end of the steam main. It is essential to pipe the steam boiler riser to the top of the counterflow system pipe. This allows a significant amount of condensate to drain back into the boiler riser, dripping through the boiler's steam chest. If this happens, it will reduce the amount of steam in the boiler by cooling it, causing it to condense. The drip for the counterflow system should originate from the end of the main near the boiler, allowing the condensate to return to the boiler. The piping arrangement is such that if the water level drops sufficiently or the boiler is surging, the steam can enter the drip line and flow into the steam main. This can cause heating problems or result in no heat at all. Here is another diagram offering an alternative piping style, which I believe is preferable and more acceptable given the proximity to the boiler, as indicated in the manufacturer's diagrams. The drop before the Hartford loop will keep a water seal between the boiler piping and the system drip.

Disclaimer: