The Difference Between Condensate and Boiler Feed Tanks

I have been asked many times over, "What is the difference between a condensate receiver and a boiler feed unit?" This can only be answered by explaining what each does. I will discuss the condensate receiver tank first.

Condensate Receiver Tank and Pump

A condensate receiver is a small tank with a low water volume that works much like a sump pump. There is a float and switch assembly that operates a pump motor to pump the water into the boiler when the water level rises enough to activate the float switch. They are used when returns cannot be piped back to the boiler, or the condensate is below the bottom of the boiler. Another use is when you do not have the proper "B" dimension, which is 30" per pound of pressure on the system between the lowest steam carrying main and the boiler water level. The downside of this is that the pump will pump water into the boiler, whether the boiler actually needs it or not. This may cause the boiler to overfill or worse. Yet the boiler may reach a low-water condition, and the pump may not have enough water to raise the boiler's water level to a proper operating level. The Makeup water is added to the boiler when using a condensate receiver, which is not beneficial for the boiler.

Boiler Feed unit

A boiler feed tank is a much larger tank in water volume. Today, most manufacturers would rather see a boiler feed tank than a condensate pump. The boiler feed unit is operated by a pump controller mounted on the boiler. The pump controller will start and stop the pump depending on the water volume in the boiler. Instead of feeding water to the by a float-operated switch. When the water level is high enough, the pump controller will shut down the pump on the boiler feed tank.

, In a nutshell, the boiler only gets water when needed and gets as much as needed. The condensate receiver will pump water whether the boiler needs water or not. Another advantage of a boiler feed tank, aside from its larger water volume, is that the pump controller is controlled by a float-operated switch, which regulates the flow of make-up water into the boiler feed tank. When makeup water is fed into the tank, the oxygen can leave the water in the tank rather than being transferred to the boiler. When oxygen is released in the boiler, it causes oxygen corrosion, creating holes at the water level. The second advantage of adding make-up water to the boiler feed tank is that the dissolved solids drop out in the tank, not in the boiler, where they collect in the smaller waterways at the bottom of the boiler, reducing water flow in the sections. In short, a boiler feed tank will extend the life of the boiler.

Both tanks are more common today than in the prior few decades, and are not restricted to large residential or commercial applications, usually around 500,000 BTUs and larger.

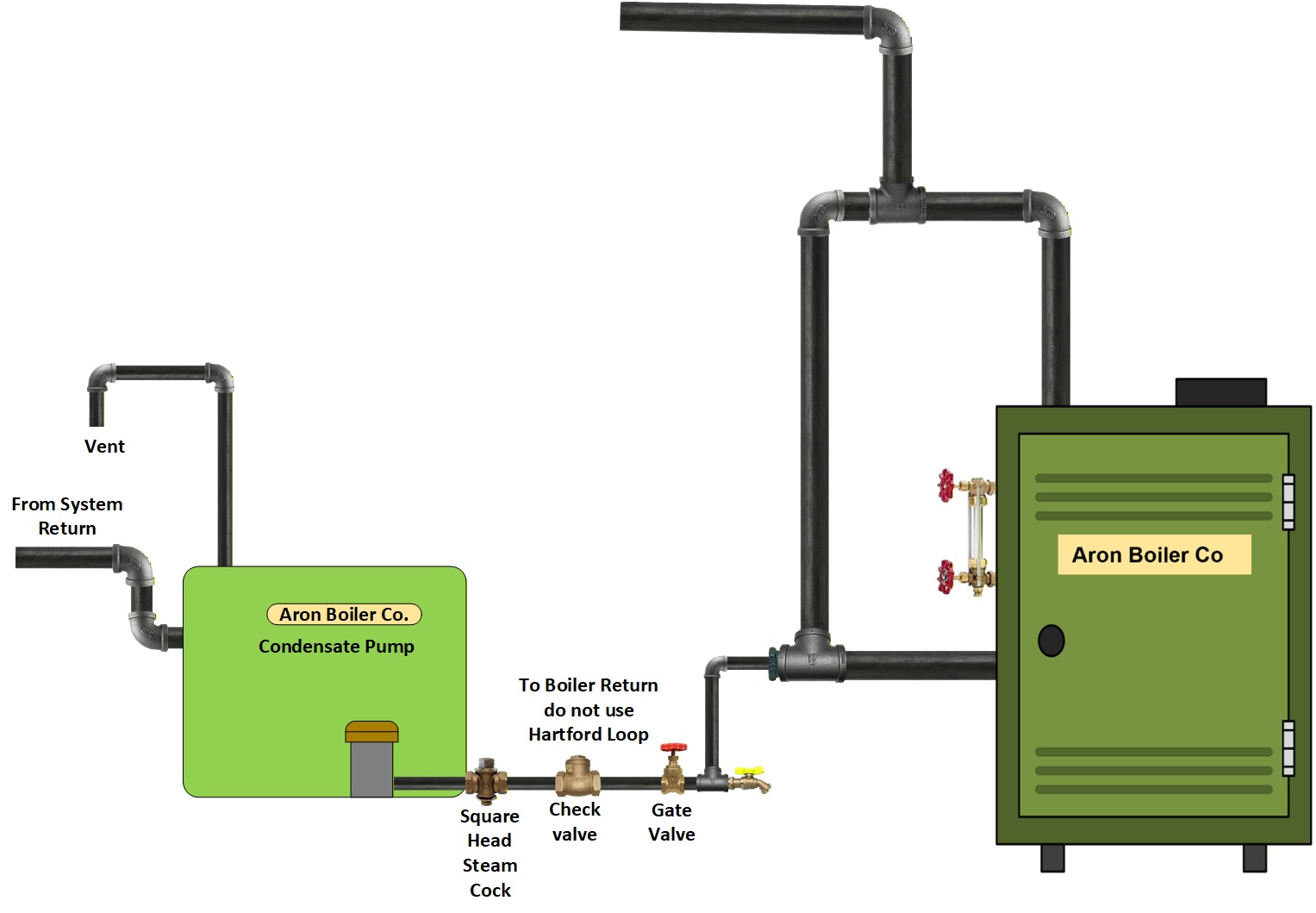

Piping the pump back to the boiler

First things first, when you decide to install a tank, you eliminate the need for an "A" or "B" dimension. For more information on A & B dimension Click Here. If you have a dry return, you will need a trap on the return line before the tank, but not right at the tank. Do not eliminate the equalizer pipe when using either of the tanks mentioned above. Even though you will not need to equalize the pressure, you still need a header drip. The equalizer now becomes a drip, so any condensate in the header will flow down the equalizer pipe to the boiler's return.

Material Needed:1. Pipe of required size. It could be black or copper, since we are below the boiler's water line.

2. Check valve same as pipe size

3. Square cock for balancing the return condensate between the pump and the boiler

4. Gate valve

5. Boiler drain

When piping the condensate back to the boiler, do not use a Hartford loop. This could cause operational problems, as water can splash up the equalizer into the header and down the boiler risers, condensing steam in the boiler's steam chest.

If the old condensate receiver or boiler feed unit is in a pit, more than likely the best choice is to leave it in the pit, probably. It is probably there for proper drainage from the heating system. Over-sizing is more critical with a condensate pump than with a boiler feed tank.