Ask Your Boiler and System Questions or Leave Your Comments Here

System zoning-how to and how not to do

Zoning has become exceedingly popular over the last couple of decades. The University of Illinois conducted extensive testing in the 1960s and found that fuel savings were achieved when buildings were zoned. The university used only cast-iron boilers for its testing. They found that applying two zones to a single-zone home reduced fuel costs. They also determined that the boiler's operating efficiency decreased slightly.

While zoning is extremely popular today, some contractors have gotten overzealous with zoning. Some zoning is beneficial, but excessive zoning could lead to higher fuel consumption and increased installation costs, unless implemented properly.

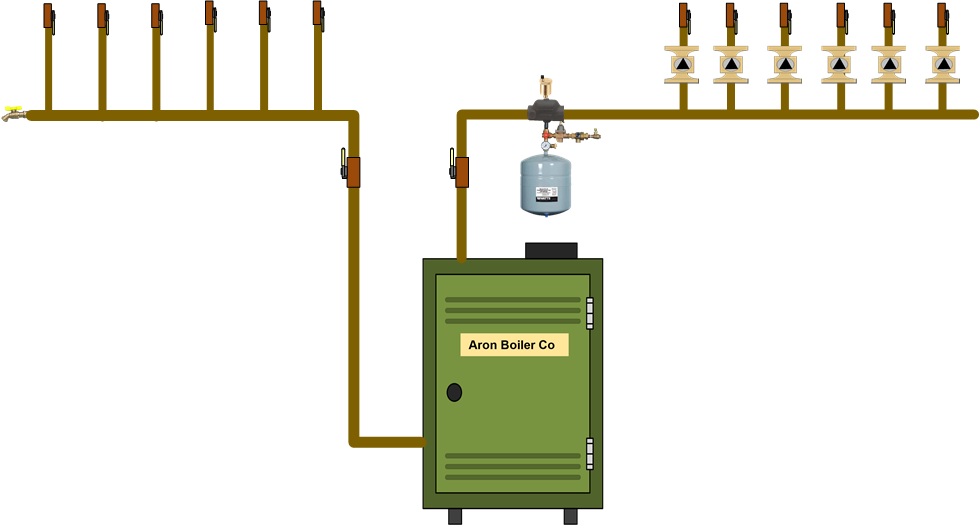

System zoning can be controlled using individual circulators or zone valves. The popularity of each is determined by its geographical location. Most zoning with circulators is done in the east, and most zoning with zone valves is done in the Midwest and the West. I have been asked many times which is better, zoning with circulators or zoning with zone valves. It is more a matter of the installing contractor's personal preference.

The argument of which is best is as old as Ford versus Chevy, Coke versus Pepsi, creating other common ongoing arguments. I am personally more concerned with the piping application than I am with how it is zoned. Below are two zoning examples: one with circulators and one with zone valves.

Today's boiler installations have moved from cast iron to more of the high-efficiency modulating condensing boilers. These newer boilers, with their 5:1 to 15:1 turn-down ratios, make zoning easier. These boilers will modulate fuel input in response to load during the heating demand cycle. Cast iron borders are still very popular as a retrofit boiler, but have one input, which means it'll always input 100% of the rated BTUs.

The only hard and fast rule that I have for zoning high-efficiency boilers is to keep the minimum zone BTU output equal to or greater than the minimum input of the boiler. If that is not feasible, there are alternative options; we will address them later.

Let us discuss zoning cast iron boilers. Since this boiler fires 100% on or off, we must be aware of how many short cycles it will experience due to the number of zones. We are looking for runtimes of 10 to 15 minutes, so having too many zones could cause severe short cycling. Even though the zone will heat properly with the boiler short cycling, it does affect the boiler's efficiency and the amount of service and maintenance required over time. I would normally try to limit the number of heating zones on a cast iron boiler to 2 or 3. If you require multiple zones, I would recommend installing a modulating condensing boiler rather than a cast-iron boiler, as modulation helps reduce short cycling. A good rule of thumb is that no zone should have a lower BTU output than the boiler's minimum firing rate.If you still wish to use a cast-iron boiler, we can address piping with more zones later.

Cast iron boilers should be operated between a 20-degree and 40-degree delta T. With special piping applications, we can work outside those parameters. To determine the flow rate through a boiler, you would use the DOE or gross output rating on the tag and divide it by 10,000. For instance, if the boiler is 100,000 BTU DOE output divided by 10,000, the maximum flow rate through the boiler would be 10 gallons per minute at a 20-degree delta T. Divide that by two, and that would be your flow rate at a 40-degree delta T. Sorry 100,000 BTU boiler should have a flow rate between 5 and 10 gallons per minute. A Flow rate higher than 10 gallons per minute in this example would cause more boiler flue gas condensation, reduce the boiler's life, and increase fuel consumption over time due to corrosion of the boiler's heat transfer surfaces.

Zoning with Zone Valves

Let's revisit the argument of circulators or zone valves. If I were using zone valves, I would have multiple zone valves and a single circulator. The best circulator for that application is a variable-speed circulator. These circulators use ECM technology, which reduces energy consumption, making it easier on the electric bill. Variable speed circulators will speed up and slow down as zones open and close. Do not confuse variable speed circulators with multi-speed circulators. The zone valve end switches can be daisy-chained together and wired back to the boiler to start or stop the boiler and circulator. There are also multizone panels for zone valves, which offer a priority zone if you have an indirect water heater.

Zoning With Circulators

When zoning with circulators, I get very concerned about the flow rate through the boiler. Most zones require less flow than the pipe is capable of handling. But most of the time, the circulators installed per zone will move more water than the zone needs. The reason for the concern would be excessive flow rate through the boiler, causing more condensation and corrosion.

For instance, a ¾” pipe, which is most common for zones, is capable of creating a flow of 4+ gallons per minute. Using the calculation above, if the boiler has four zones, it can move 16 gallons of water per minute when all four zones are calling simultaneously. This would shorten the life of the cast-iron boiler. As shown in the following diagram, this could pose a problem.

I feel that if zoning with the circulator, it would be best to pipe the cast iron boiler utilizing primary-secondary. When primary-secondary piping is used, the system flow is separated from the boiler flow. When piped in this manner, you can control the amount of flow through the boiler with a flow regulator. The flow rate through the boiler can differ from that through the system with this style of piping.

For more information on cast iron boiler protection, you can use the search box in the upper right-hand corner and type boiler protection, buffer tanks, primary secondary piping, bypass piping, and three- or four-way mixing valves. You will see that there are many ways to protect cast iron boilers when needed.

Disclaimer: The information found on this website is for informational purposes only. All preventive maintenance, service, and installations should be reviewed on a per-job basis. Any work on your heating system should be performed only by qualified, experienced personnel. Comfort-Calc or its personnel accepts no responsibility for improper information, application, damage to property or bodily injury from applied information found on this website as it should be reviewed by a professional.