When installing a new boiler, furnace, air conditioning system, or a replacement appliance, it must never be oversized. With the growing popularity of mod/con boilers, which modulate the fuel input up and down based on the supply and return water sensors, setpoint temperature, and software in the control, Most of the circulators used today are single-speed circulators, which will always flow the same amount of water through the boiler at all times. If the flow through the boiler is the same all the time, the only difference in heat output is the fuel input. With these boilers, the fuel input varies with outdoor temperature, requiring different system outputs depending on the water temperature. The amount of modulation depends on supply and return temperatures, as well as the control software, which calculates the water temperature to be sent to the radiation to match the heat loss. The more heat emitters you have and the larger the water volume, the better suited a mod/con boiler is.

These boilers should operate with an outdoor reset (ODR) control that includes ODR, which will reduce the system water temperature as the outside air temperature increases. These boilers are typically piped in a primary/secondary (p/s) configuration. As the fuel input changes, the water output temperature changes. For example, if you are inputting 80,000 BTUs into 8 gpm, each gallon of flow will absorb 10,000 BTUs per hour. If the boiler has a 4:1 turn down, which means dividing the input by the turn down (80,000/4 = 20,000), while the flow is still 8 gpm, each gallon now absorbs 2,500 BTUs per hour. This is great if all the water carrying these BTUs were to flow out to the system and dissipate these BTUs in the home. With multiple zones in the home, each zone is smaller than the boiler size. A small zone would not have a problem eliminating these BTUs.

Let's oversize the boiler due to not doing a proper heat loss. Let's say the new boiler is sized based on the amount of radiation load, or it is installed with the same size boiler that will be removed. The same system as above now features a 150,000 BTU boiler with a 5:1 turn-down ratio (150,000/5 = 30,000) instead of the 80,000 BTU boiler. This boiler requires approximately 15 gallons per minute (gpm) of flow. On a low fire, each gallon absorbs approximately 2,000 BTUs as it passes through the boiler at the lower input. This sounds like there is no problem. This is due to the high flow needed by the boiler. The higher flow through the boiler and lower flow in the system causes the boiler to short-cycle, thus reducing the operating AFUE efficiency.

We will end up with reverse flow between the closely spaced tees on the primary loop. This means we pre-heat the return water. As warmer water enters the boiler, the internal water temperature increases more quickly, causing the boiler to shut down sooner. If the water temperature changes rapidly enough, the fan is constantly adjusting to the proper RPM. It will cool rapidly and run for a short cycle again. The shorter the cycle, the less efficient the operation becomes. As boilers increase in size, the required flow through them increases. As the flow required for larger boilers is applied to smaller systems or, worse yet, oversized boilers in a zoned system, the possibility of short cycling becomes more likely. I have seen mod/con boilers reach their high limit so quickly that they don't have a chance to modulate. I also see many units installed without the outdoor reset control connected.

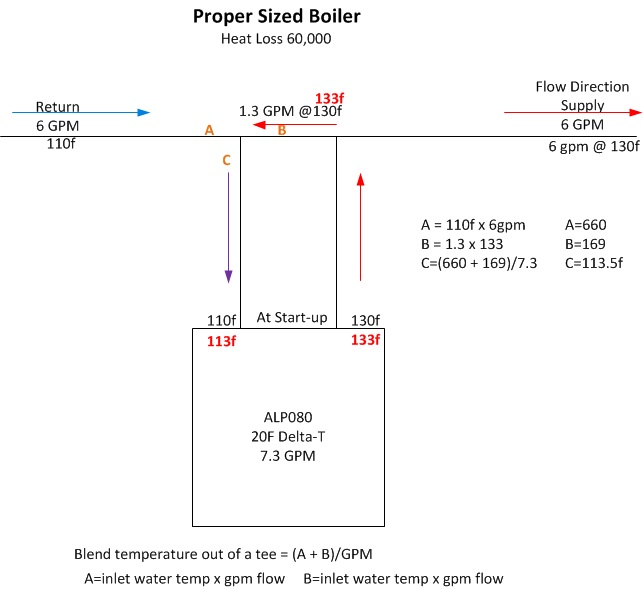

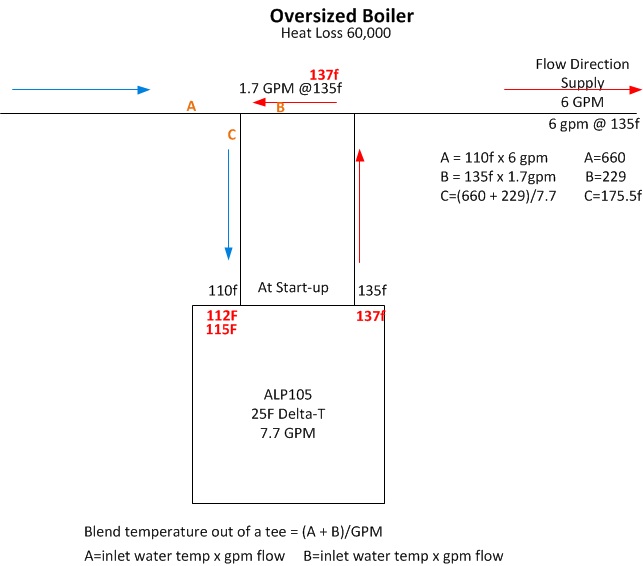

With primary/secondary piping, water can flow in either direction between the tees or have no flow between the tees. The diagrams below illustrate the changes in flow and temperature within the boiler piping as boilers become more oversized. The numbers increase as the boiler continues to run. We are assuming a heat loss of 60,000 BTUs. The system requirement is 6 gpm. We are assuming all zones are running, or there is a single zone in the home. If the home is zoned and only one zone is running, the conditions get worse. As we approach the setpoint temperature and the boiler starts modulating back, conditions improve. Most, if not all, mod/con boilers have a display that shows the number of cycles and runtime hours. If you have this menu option, you can determine the average run time. To calculate the average runtime, use this formula.

Average runtime minutes = (runtime hours x 60) /# cycles

A good time would be 20 minutes or more. If you have insufficient runtime, the boiler efficiency is affected, and you may experience premature part failure. To change this runtime, check the control to see if you can change the maximum fan speed. If so, it can be reduced to improve the modulation rate and produce a slower temperature rise. Unfortunately, you will likely not be able to reduce the minimum fan speed, which is the lower end of the modulation range.

The following diagrams show the boiler at maximum fan speed, which is where you will be with larger delta-T's normally at start-up on each thermostat demand.

This shows a close match between the heat loss and the boiler choice.

This shows the boiler being 1 size too large

This boiler is two sizes too large, which is not uncommon.