Piping Multiple Indirect Water Heaters

I have been asked lately about piping multiple indirect water heaters. This seems to be a growing trend. Multiple indirect water tanks can actually be applied differently and the application can change the piping. For instance, you can have a home that would install multiple tanks. You may have a tank for the hot water needs of a home but a separate indirect water heater tank for just a whirlpool tub. In another application you may have a hot water tank at two separate locations in the home due to the location of water needs in the home. There may be an indirect tank at either end of the basement due to the fact this is where most of the hot water demand is. In the above applications the tanks would be heated independently.

Another application would be to install multiple indirect water heaters all connected together to gain water storage like may be required in an apartment building. This application would require all the tanks to heat at the same time. The draw from the tanks would be all tanks at the same time not a single tank at a time. A multi-family building may also include a circulated hot water loop. I have seen some building with 3 - 4 indirect water heaters all piped together in tandem. There were piped to heat all at the same time from one or more boilers.

All of the above applications may be done with one or multiple boilers. The boiler(s) may also be used for space heating in addition to making domestic hot water. Below are some drawings to show piping from one or more boilers with and without space heating.

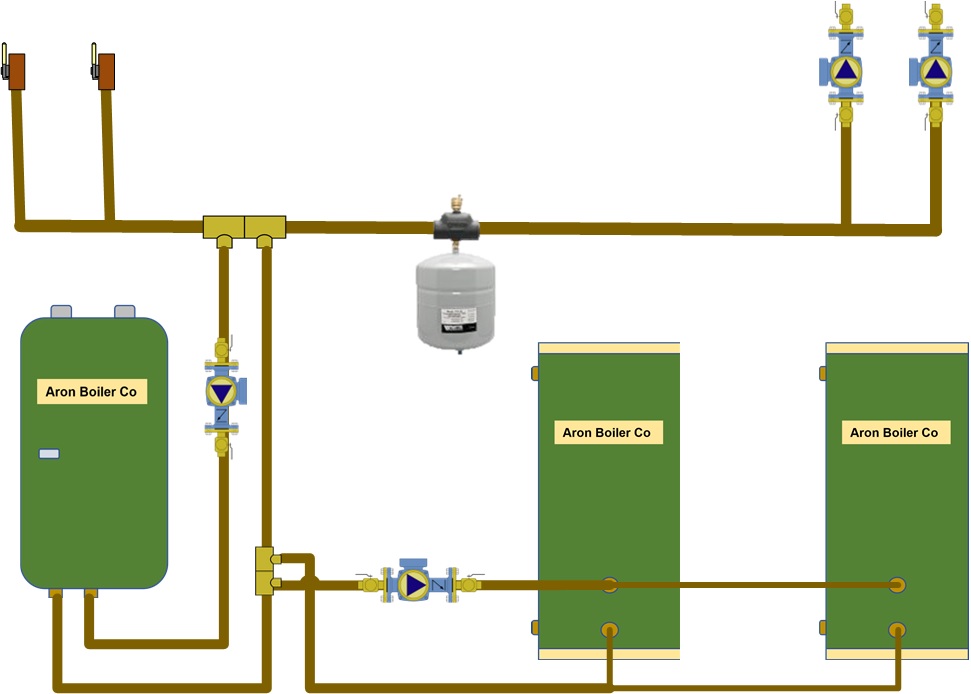

Two boilers, multiple tanks with reverse return piping

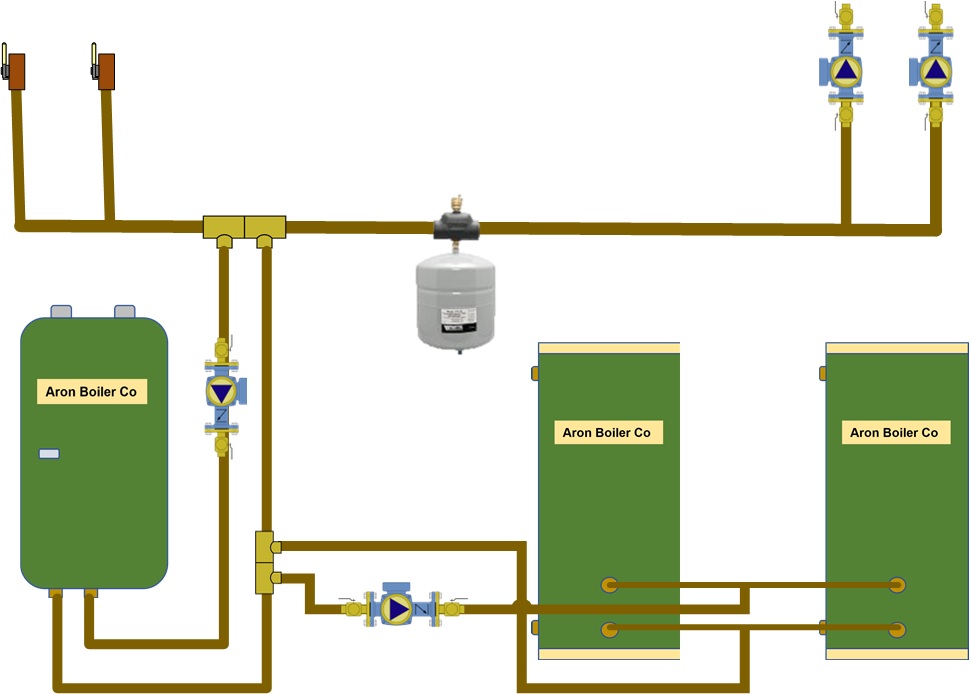

The drawing above is using one or more boilers with multiple indirect water heaters. All tanks heat at the same time at the same rate. The pump would normally be placed on the supply pipe pumping into the tanks and sized for all the coils, fittings and components. This is piped as what we call a reverse return piping system. By utilizing reverse return the flow in the tanks will balance itself to make sure all the tanks get the same flow. This also means they will heat equally well. The tank controls will be wired in series so one control will operate for all the tanks and the balance of the controls are set higher as back-up high limits. If we just ran the supply and return pipes to the tanks in parallel flow (below) the tanks would heat unevenly. Water flow is always the path of least resistance.Parallel Piping Multiple Tanks - Not recommended

The flow in this application would be greater in the tank closest to the boiler and less in the last tank. This would mean the first tank gets the hottest and the last tank would not be quite as hot and may not heat to setpoint depending on control settings. I would not use this type of piping for IWH tanks due to unbalanced boiler water flow through the IWH coils.

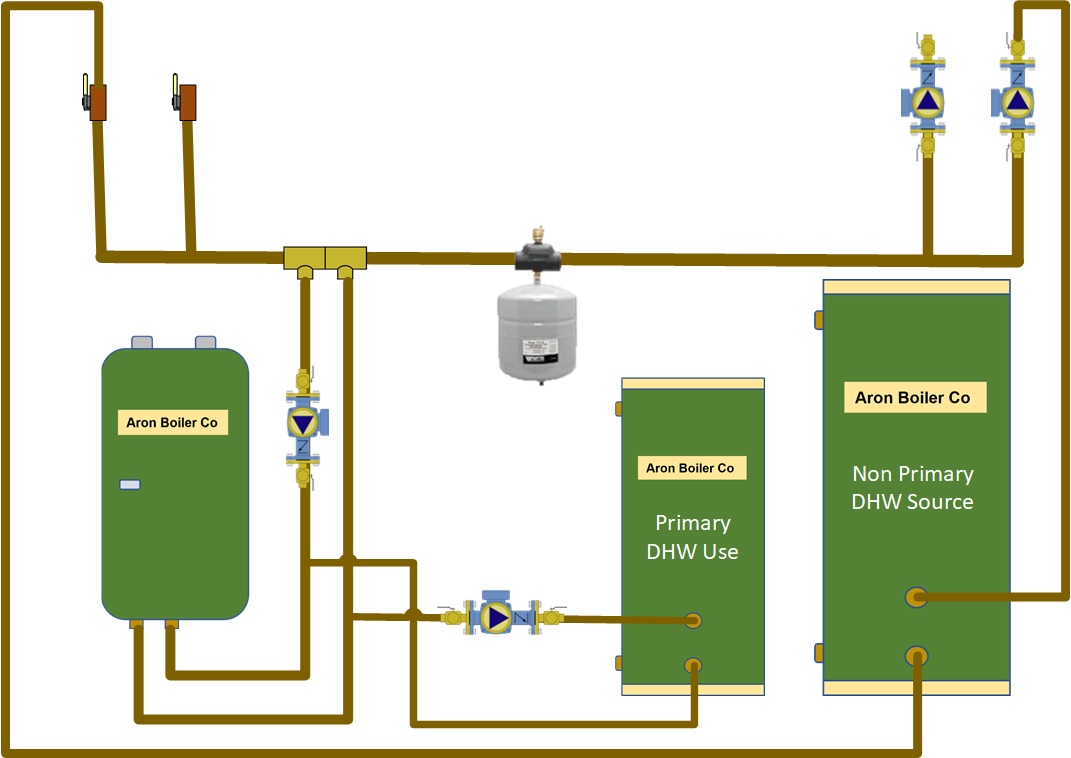

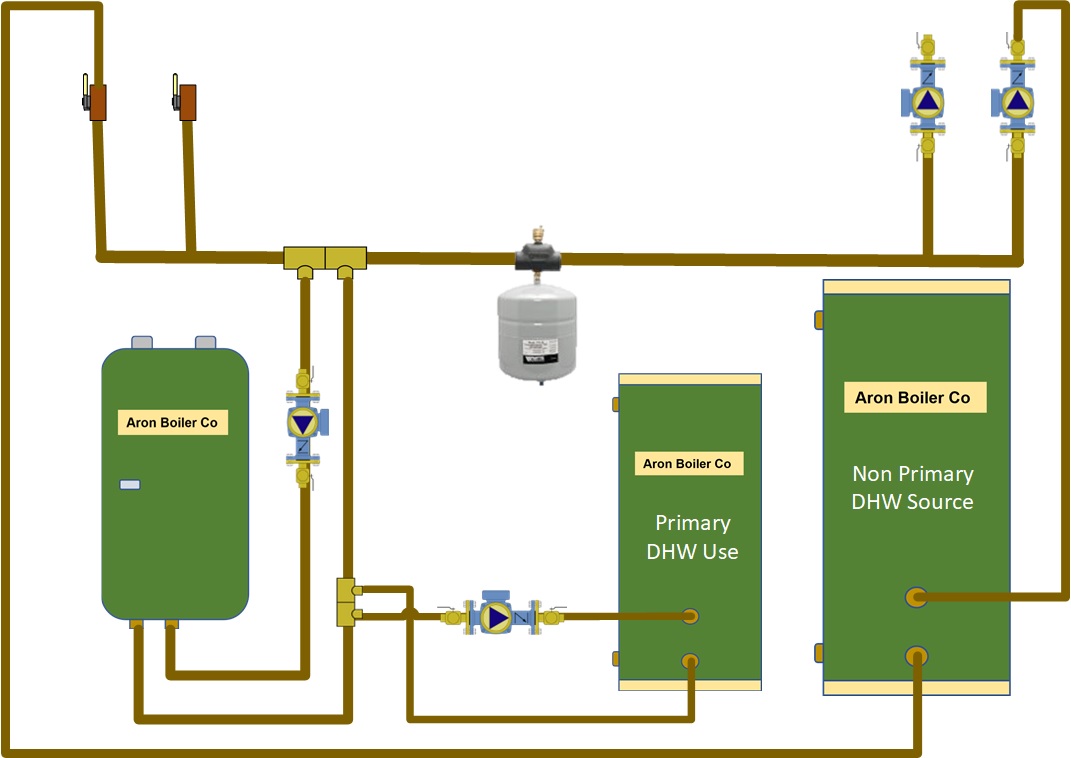

One or more boilers, Multiple tanks - tanks heat independently

Another Piping Option