Piping an Indirect Tank into a Steam Boiler

Drawings on this page are from my online or live seminar

Piping an indirect or baseboard to a steam boiler

Caution: All drawings are conceptual drawings for illustration purposes only and may be incomplete. More specific drawings may be needed for your application.

Piping an indirect water heater into a steam boiler is not an uncommon application with gas or oil-fired steam boilers. There are a few bits of information we need to talk about before doing the piping.

For information adding HW baseboard at the same level or above the steam boiler click here

Below are some guidelines to follow when istalling h/w baseboard or an indirect water heaters at the same level as the boiler.

- We can return the water from the indirect to a boiler taping normally in the opposite end of the boiler from the supply. This will avoid short cycling of the water within the boiler. If you pipe into the steam system return pipe the pipe must be on the boiler side of the Hartford loop.

- The boiler should have at least one 1" or larger tapping higher in the boiler than the return tapping.

- Use an aquastat to keep the boiler from creating steam on a demand for DHW or HW baseboard only. A separate control taping in the boiler and slightly higher than the IWH pipe taping works best.

- The control taping can be as small as 1/2" for the control well. A strap on control on the piping works and is a bit harder to stop the boiler from steaming. A control in the boiler is much more accurate.

- It is best to use a bronze or stainless circulator to pump this water. Although many have used the smaller wet rotor circulators, it is best to use a three-piece circulator. The circulator must pump away from the boiler. Think of the boiler as the expansion tank connection

- The piping from the supply tapping must elbow down toward the floor and mount the circulator close to the floor to keep the live steam away from the inlet of the circulator in case of surging water. If steam enters the circulator it can cause the circulator to fail.

- It is a good idea to install a strainer before the circulator as some dirt my get disturbed in the bottom of the steam boiler with the circulation of water. We want to keep the debris out of the circulator, radiation and/or IWH coil.

- The use of a check valve is recommended

- When doing heating only I would suggest a bypass around the boiler from return to supply to keep too hot of water going to the the radiation and flashing in the radiation. If doing just an IWH no bypass is required.

IWH and Baseboard on the same level as the boiler

If the heat or an indirect water heater is on the same level as the steam boiler you can just pipe it as usual. Check the boiler manufacturer's directions for information as to which boiler tapings to use for supply and return pipes from the radiation.

This application would not require the use of a pressure relief valve on the heating loop or expansion tank due to piping being opern the the boiler.

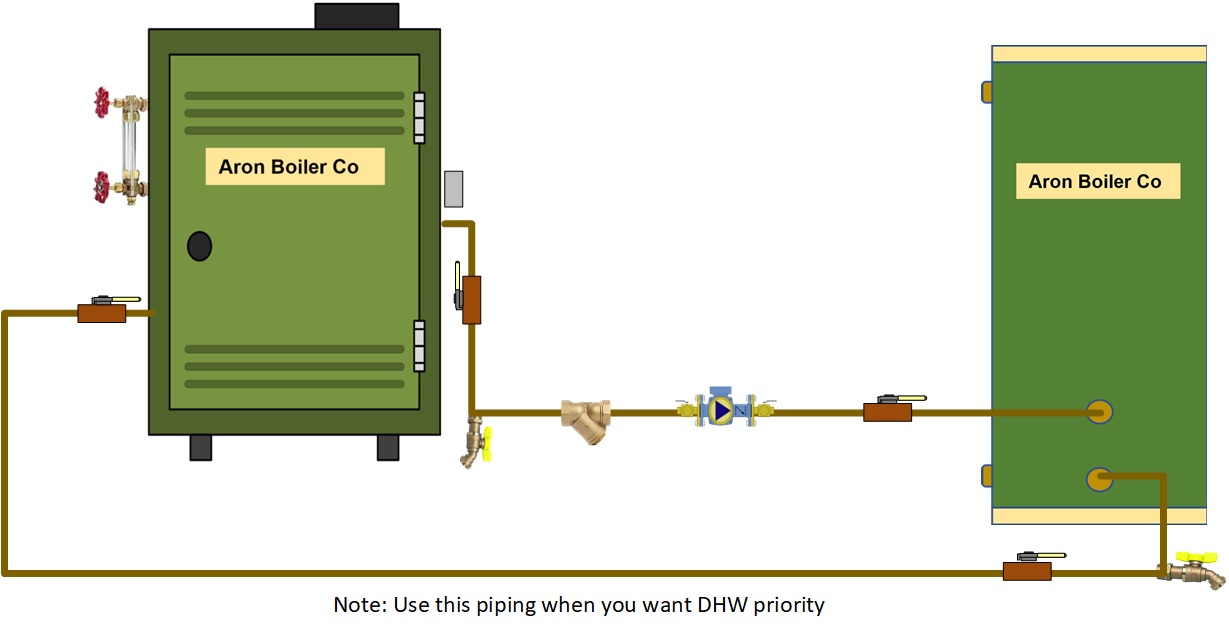

This application is used when you want DWH Priority

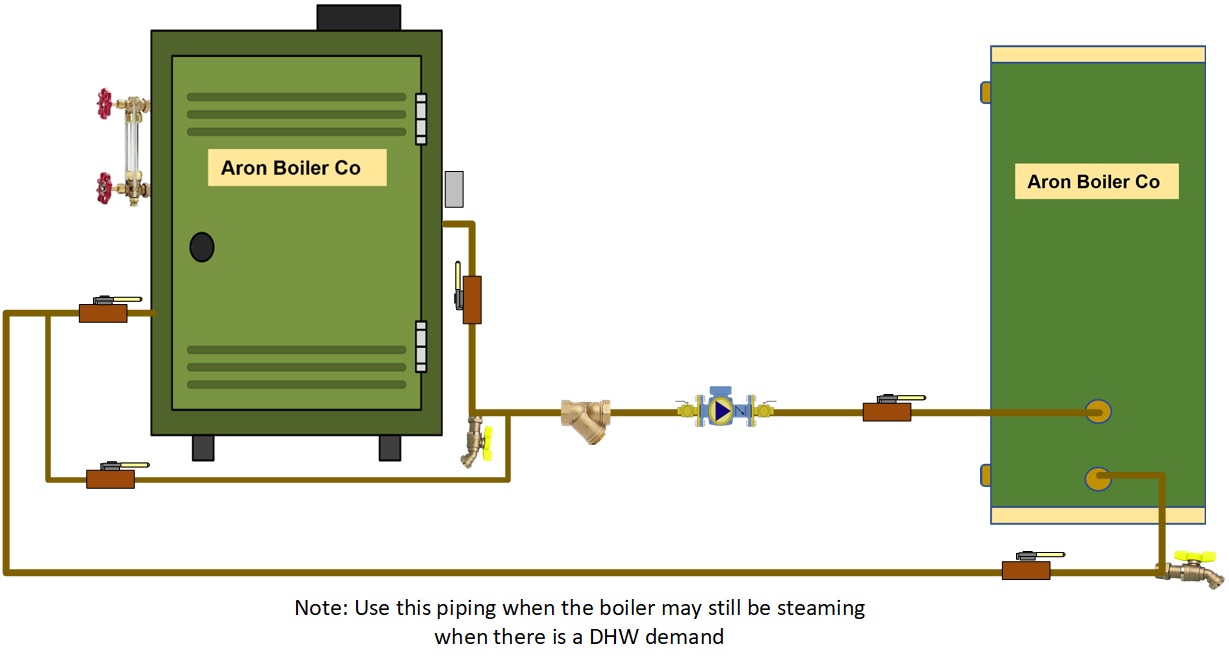

This application is used when you are not prioritizing DHW

This would work for the water heater or the basement hot water loop, or both at the same time. It is important to make sure when supply pipe leaves the boiler the piping goes down near the floor. Keep the circulator(s) as low as possible to keep steam from enteribg the water loop and ruining the circulator.

Wiring IWH and/or wet heat zone on steam boiler

- Control wiring - IWH to steam boiler no Priority, boiler is large enough to do both heating and IWH at the same time.

- Priority Control wiring - IWH to steam boiler using a Taco SR501 relay and L6006C aquastat to create DHW Priority

- Priority Control wiring - using a Taco SR502 multi-zone using priority switch.

Disclaimer: The information found on this website is for informational purposes only. All preventive maintenance, service, installations should be reviewed on a per job situation. Any work performed on your heating system should be performed by qualified and experienced personnel only. Comfort-Calc or its personnel accepts no responsibility for improper information, application, damage to property or bodily injury from applied information found on this website as it should be reviewed by a professional.