All about Bypass Piping

Although there are many ways to protect residential cast iron boilers from flue gas condensation discussed Cast Iron Boiler Protection. This article addresses boiler bypass piping in more detail.

Through the decades as the Federal Government raised the minimum efficiency of cast iron boilers, one-way manufacturers could meet the code is to reduce the water volume in the boiler. Reducing the water volume does not change the water content of the system, just the boiler. Unfortunately, this can cause an increase of flue gas condensation due to the temperature of return water being below dew point. The water in the casting sections was cool and the flue ways were hot. This is like a cold drink on a hot summer day.

In the fifties an engineer from Bell & Gossett Co. introduced a way to protect the cast iron boiler from condensing in the flue ways by changing the near boiler piping. The detriment of a boiler condensing is flue gases containing multiple acids. These acids attack the cast iron when the flue ways are wet. When the boiler flue passes dry, the acids almost become dormant.

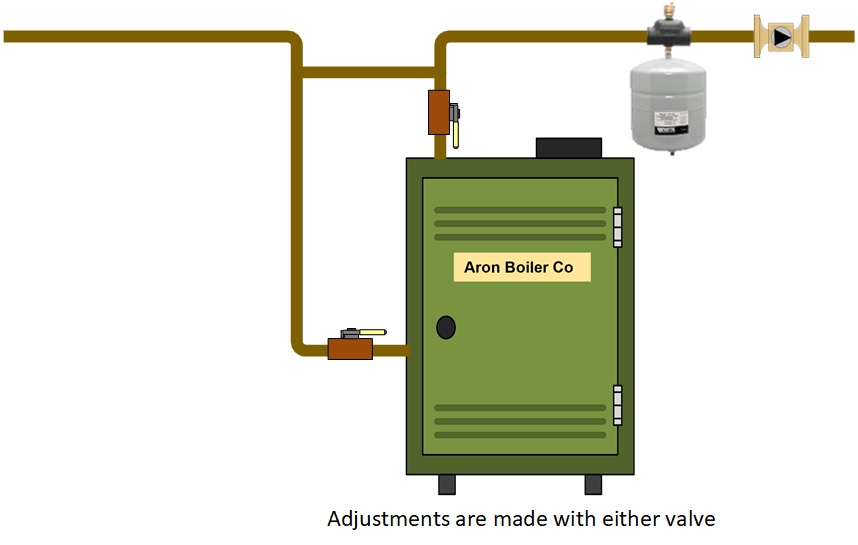

Early days most of the boilers had large water volume and could be piped with a system bypass. This means the water returns from the system, enters the boiler, mixes with the existing boiler water, gets heated and exits the supply side of the boiler. After leaving the boiler some of the water is drawn from the supply piping and introduced into the return water. This will preheat the return water to reduce flue gas condensation in the boiler. The system bypass keeps full flow through the boiler and reduces flow in the system.

As the efficiency standards increased and the water volume and boiler physical size decreased, the need for a bypass became more important. But piping did change from a system bypass to a boiler bypass. The system bypass was first designed for larger water volume boilers. The hot supply water exits the boiler, a portion of the supply water will be directed to the cooler return water. The idea is to preheat the return above condensing temperature before it enters the boiler. The downside of the system bypass is, depending on the water volume or return temperature it may never get warm enough to get the return temperature above condensing temperature. The shoulder seasons will be more of a problem then wintertime.

Boiler Bypass Piping

If you are not sure if your bypass is a system or boiler bypass feel the bypass when the boiler is running. The bypass should be the same temperature as the return pipe and cooler than the supply pipe.

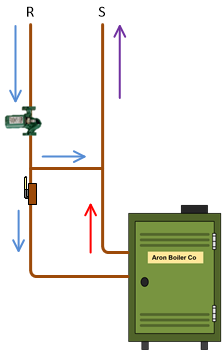

Boiler Bypass with return and supply side circulator Locations

System Bypass Piping

System bypass piping used to be quite common years ago and still is somewhat common with commercial cast iron boilers. Today there are far better ways of protecting commercial boilers. Oh well, back to residential boilers. When piping a system bypass the bypass pipe is usually half or less the diameter of the supply and return manifold pipes and many times one-half inch copper. A system bypass should have a valve in the bypass to adjust the amount of mixed water bypassing to the boiler return pipe. If there is a bypass pipe and you're not sure if it's a system bypass or not, feel the pipe when the boiler is running. If it is a system bypass the bypass pipe will be the same temperature as the boiler supply and hotter than the boiler return pipe.

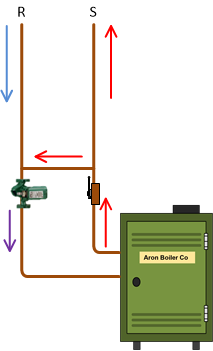

System Bypass with return and supply side circulator Locations

Disclaimer: The information found on this website is for informational purposes only. All preventive maintenance, service, installations should be reviewed on a per-job situation. Any work performed on your heating system should be performed by qualified and experienced personnel only. Comfort-Calc or its personnel accepts no responsibility for improper information, application, damage to property or bodily injury from applied information found on this website.