Steaming crabs

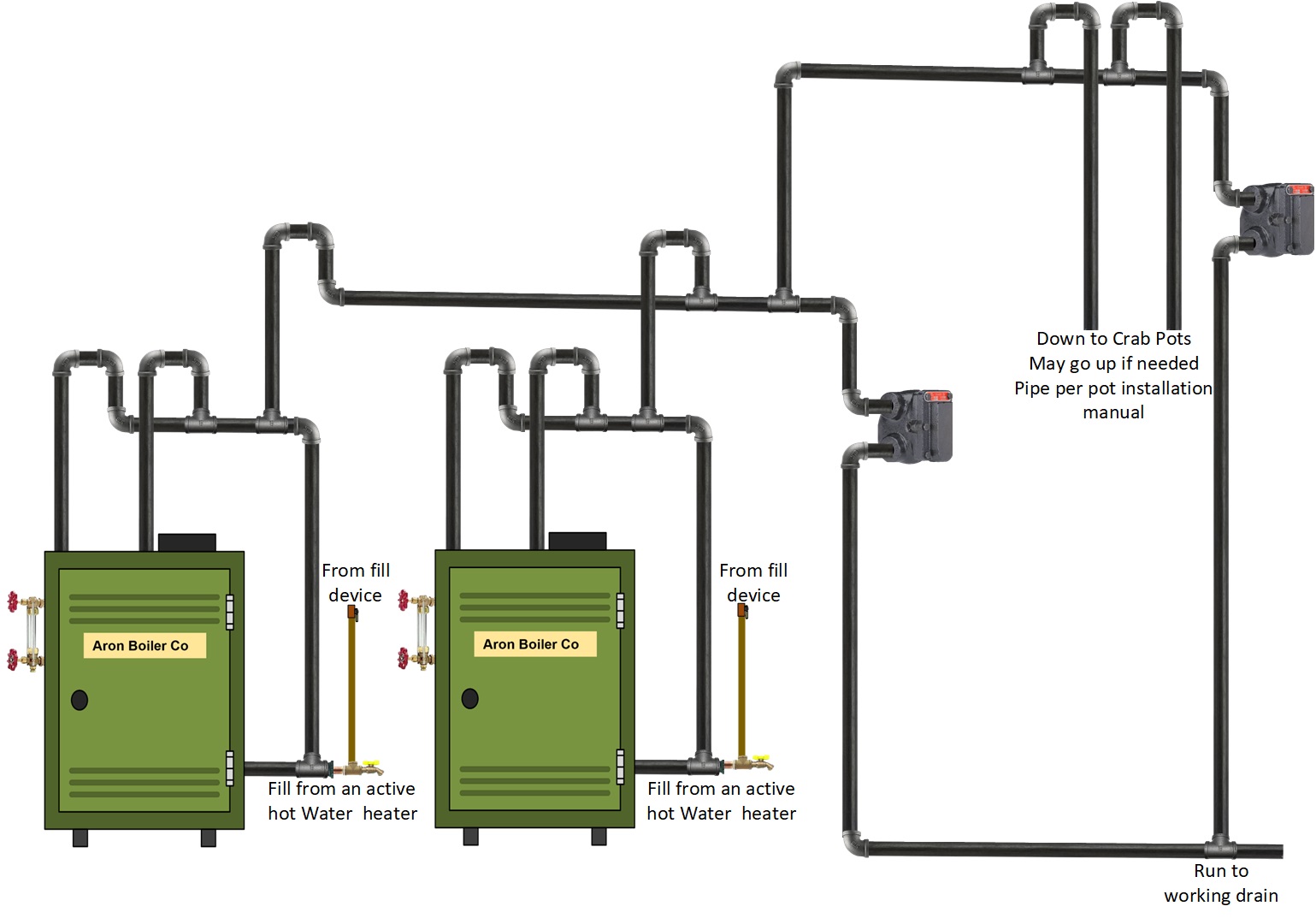

Caution: All drawings are conceptual drawings for illustration purposes only and may be incomplete.In the coastal areas of the Chesapeake Bay and inland water ways the steaming and selling of crabs is a business as is a lot of other coastal areas. There is nothing like a good steaming hot Maryland Blue crab. The question is asked many times how to pipe steam boilers to do the steaming of these scrumptious crustaceans. There are many ways to pipe the boilers but here one of the best piping diagrams I have come across. It came from an old friend named Owen Hartlove of Baltimore.

We all know when it comes to using a steam boiler for anything other than steam heating the condensate gets put down the drain. That means we add a whole lot of fresh water, so the life expectancy of the boiler is greatly reduced. I have a list below of what should be done from sizing to piping which has given us the longest life from a steam boiler than any other diagram I have seen. The original installation may be more expensive, but they work better and last longer, so it is worth it to do a better job up front and save $$$ overall. This gives us the driest steam for better tasting crabs. Remember our installations affect the taste of the crab and success of our customer.

1. Calculate 32,000 BTU's or 133.3 sq. ft. per bushel of crabs

If you have 5 - 2 bushel pots the boiler requirement is 320,000 BTU's net output or 1333 sq ft of steam

2. Preheat feed water through domestic hot water coil or preferably from a hot water heater

Adding hot water will get rid of oxygen and dissolved solids before entering the boiler.

I would rather do this from a water heater than a domestic hot water coil in the boiler.

As cold water would be drawn through the coil it would kill most of the steam in the Boiler.

3. Install at least two boiler risers from the boiler. Make the header as high as possible or use a dropped header on boiler and system header.

4. Use as high a riser as possible off crab pot

4. Insulate all piping

5. Keep header velocity below 25 fps

6. Keep system piping velocity below 50 feet per second

7. Clean the boiler well by heating it up and skimming the boiler very well, do not add chemicals.

8. Use a fast feeder for each boiler. Most electronic feeders feed too slowly. Consider an MM 101 feeder.

9. Two boilers are more efficient than one as the steaming load changes constantly.

FT Traps are only required when you have more than one boiler.

Disclaimer: The information found on this web site is for informational purposes only. All preventive maintenance, service, installations should be reviewed on a per-job situation. Any work performed on your heating system should be performed by qualified and experienced personnel only. Comfort-Calc or its personnel accepts no responsibility for improper information, application, damage to property or bodily injury from applied information found on this web site.