Circulator Sizing for Boilers and Indirect Water Heaters (IWH)

It would be a good idea if you have not viewed our Components Seminars Part 2nd and 3rd or reviewed and understand the webpage Circulator Sizing for Boilers and Systems.

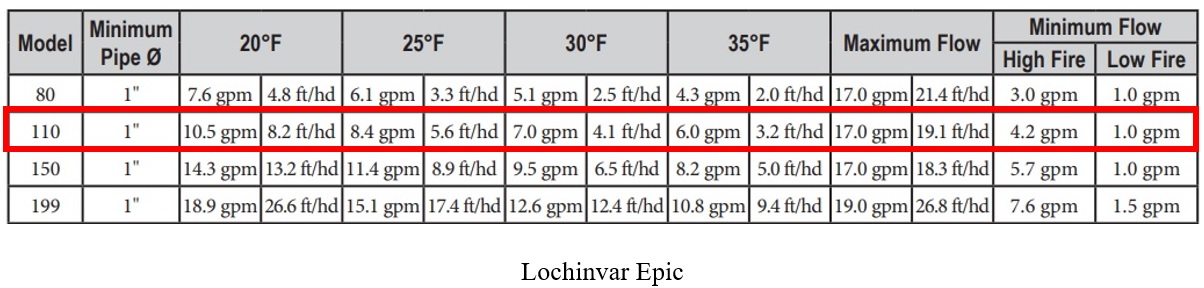

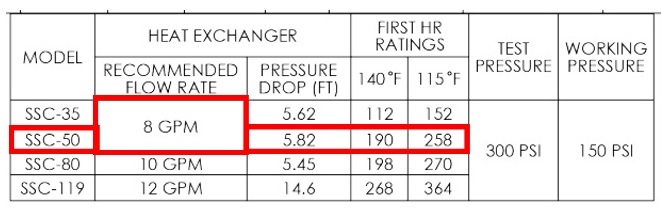

There is information you will need before determining the circulator size for the IWH. Let's assume the boiler and IWH are not installed yet. Before I can address circulator sizing, you will need to gather some of the following information using the Lochinvar boiler manufacturer's literature, HTP Superstor literature, and installation manuals.

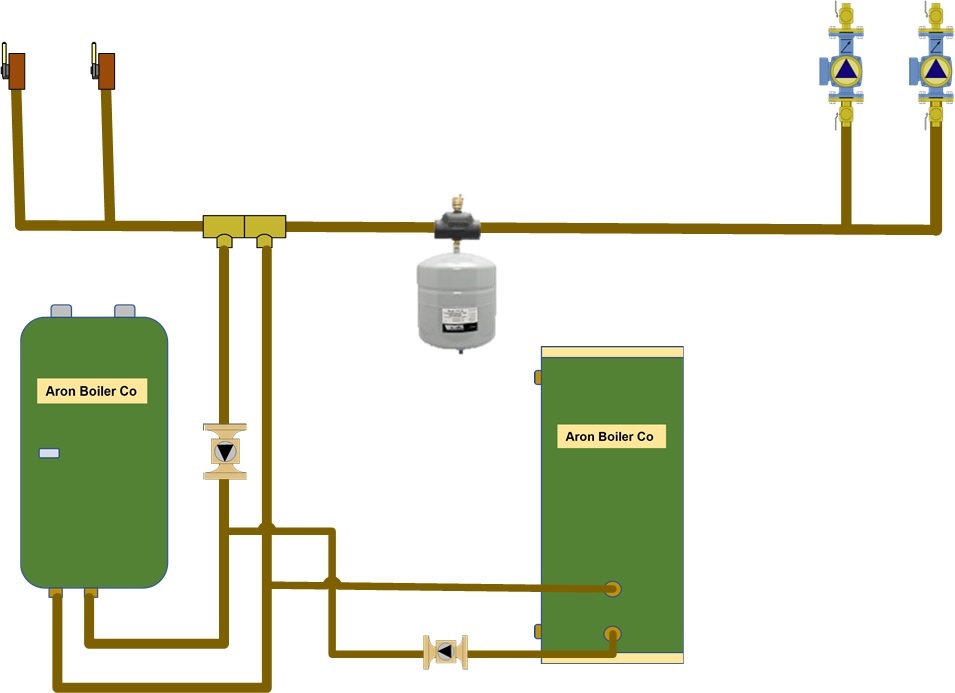

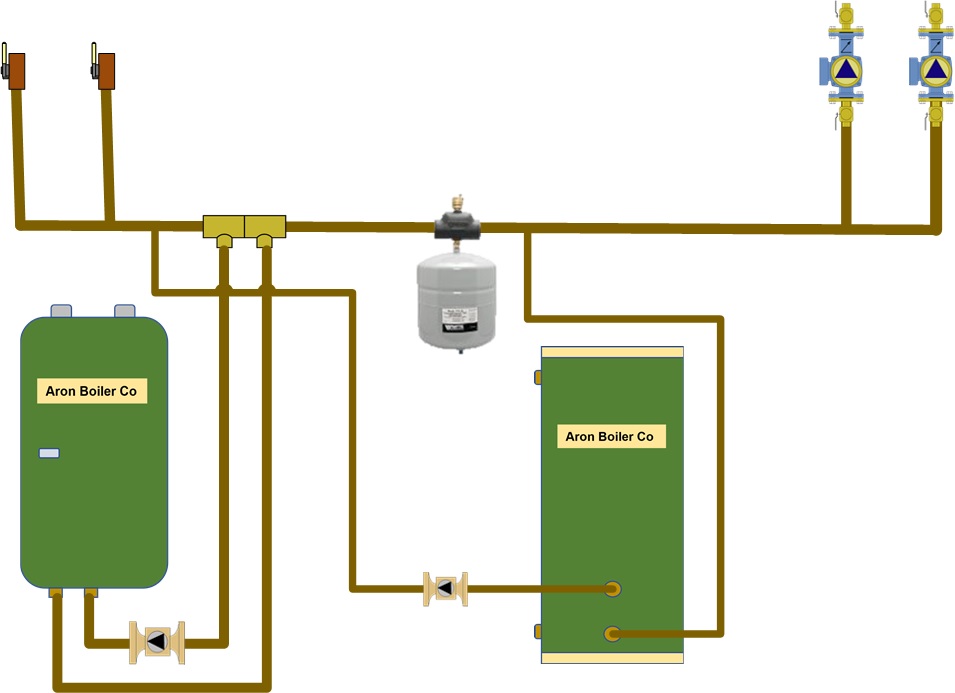

- Is the boiler going to be piped with manifold piping

- Is the boiler going to be piped with P/S piping

- Is the IWH going to be piped directly on the boiler pipes

- If the boiler is piped as P/S, but the IWH will be piped on the system piping as a separate zone.

- The resistance through the IWH

- The resistance through the boiler

- GPM flow required through the IWH

- The total length of straight pipe and the number and type of all fittings

I will show two examples, one applied to a high efficiency boiler piped directly off the boiler piping, the highest resistance, and off the system piping as a separate independent zone, normally the lowest resistance application.

Look at the information from the manufacturer's information. Below are excerpts of both.

HTP Superstor

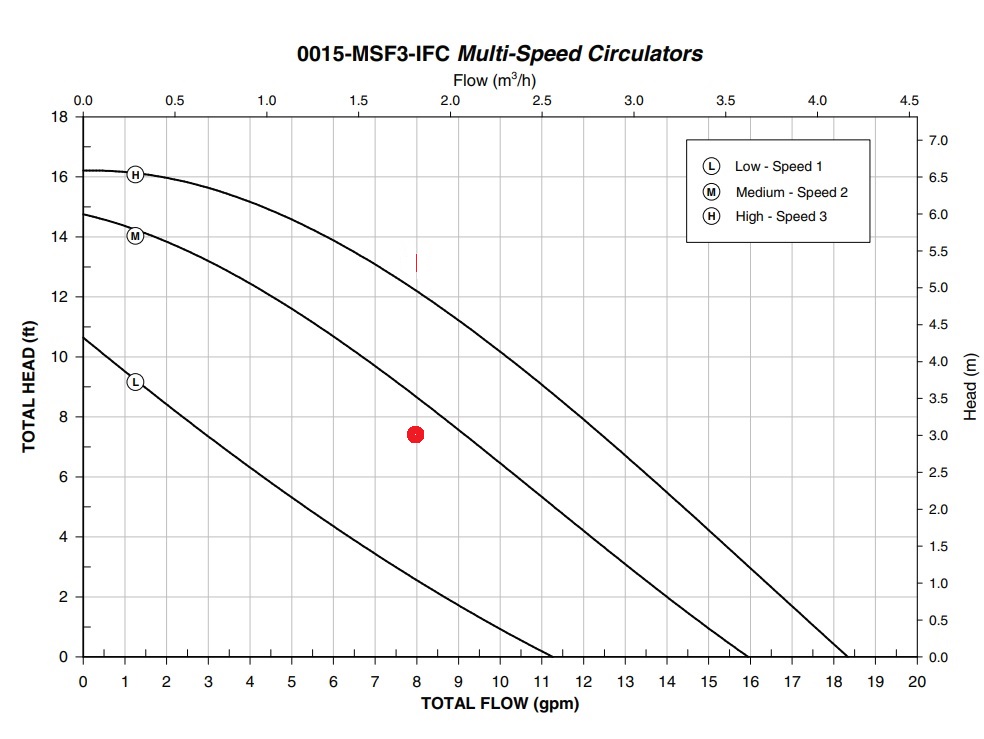

For this example, we must assume a boiler and IWH tank size. We will select a boiler that meets our calculated heat loss of 92,000 BTUs and install an EP110N and a Superstor SSC-50 IWH. Next, what Delta-T do we want to use? I will pick 25f. We now know the boiler spec is 8.4 gpm @ 5.6 ft. hd. The SSC-50 also requires 8 gpm at a head of 5.82 ft. This is a good match. When the flow of the IWH falls between the minimum and maximum flow of the boiler, this makes life much easier.

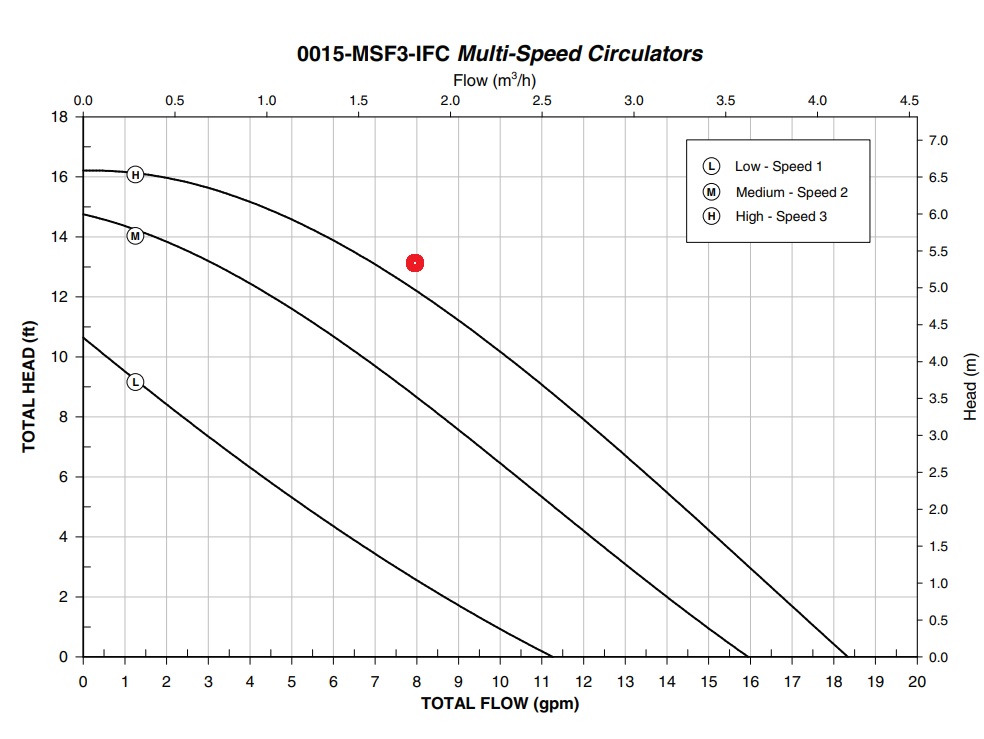

From our Pipe Sizing for Boilers and Systems webpage we know we should use a 1” copper pipe. We should add the Ft. Hd. Figures together. 5.6 + 5.82 = 11.42 Ft. hd. Calculate the Ft Hd. Now calculate the Ft. Hd. from the piping. I will add another 1.5. 11.42+ 1.5 = 12.92.

A good choice here would be a Taco 0015 on High speed. The pump will run on its curve, so it will really be running at about 12.25 ft head at just under 8 gpm. I will not confuse this at this time with calculating different flow rates and how that applies to larger boilers. Just keep the IWH flow rates within the flow rates of the boiler.

Let's look at another example where the IWH is piped as a separate zone off the system piping.

When the IWH is piped as a separate zone on the system piping, you will not need to add the boiler heat exchanger resistance (ft. hd.) to the calculation. Looking at the above calculation and a total Ft. Hd. of 12.92, and deducting 5.6 Ft. Hd. For the boilers, we will now size the circulator for a total of 12.92 - 5.6 = 7.32 ft. head, and will still require an 8 gpm flow.

Again, the pump will always run on its curve, so the flow rate and Ft. Hd. It will be slightly higher, but not enough to be a problem.

The above calculation would also apply to a cast-iron boiler. The big difference is that a cast iron boiler has almost "0" Ft. Hd. through the boiler.

Disclaimer: The information found on this website is for informational purposes only. Any preventive maintenance, service, or installation should be reviewed on a per-job basis. Any work performed on your heating system should be performed by qualified and experienced personnel only. Comfort-Calc or its personnel accepts no responsibility for improper information, application, damage to property or bodily injury from applied information found on this website as it should be reviewed by a professional.