Heating Pipe Sizing the Easy Way

I am going to start by saying, tapping size does not dictate a pipe size. Sizing for boilers, systems, zones, and indirect water heater pipes isn't that hard. I have seen many job sites where pipe sizing is part of the problem. It is usually too small; if it were slightly larger, that would not be a significant problem. If the pipe size is too small, you will reduce the flow, increase the velocity, and deliver less btu's.p

To size a pipe properly, you need to know two basic things: the needed flow and BTU requirement. This information is available through manufacturers' spec sheets or by calculating the heat loss of a home or zone. Using the information provided on this webpage, you can calculate the pipe size for boiler manifold sizes, system piping, and indirect water heater pipes.

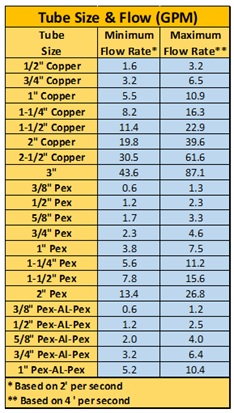

There are many charts to follow by different manufacturers, but I prefer the quick chart supplied by Caleffi, a manufacturer of boiler system components, but not boilers or circulators.

Pipe sizing for Boiler Manifold

Let's assume we have a boiler with a DOE output of 75,000, sized by using a Manual J heat loss. The home is already zoned into three zones (3 thermostats for heating). The zones are all ¾” piping. The boiler tapping is 1-1/4".

We would start by sizing the boiler manifold, which is the piping leaving the boiler, and the zone pipes are attached to the manifold. As stated above, the boiler has a 3/4" taping, but does that mean we need a 1-1/4" manifold? It does not. First, let's look at the chart from Caleffi.

Using the chart, we see that if we have a 75,000 BTU boiler, the header can be 1" pipe instead of 1-1/4" pipe. Would it hurt to use 1-1/4" pipe? No, that would be OK as it is close. Using 1” pipe would mean smaller components on the header, such as air separator, valves, and pipe fittings.

The ¾” zone pipes are already existing, and we would not be re-piping all the zones. We must address the flow and size the circulators for the required flow in the zones. My preference would be to use one circulator and zone valves. But others would prefer zone circulators. We do discuss this on another page.

Pipe sizing for Indirect water heater

If we are adding an indirect water heater, we need to size the pipe that will be added to the boiler manifold. Many indirect water heaters are tapped with a ¾” taping and have a ¾” pipe attached to them. This may be acceptable or not, depending on the tank's specifications.

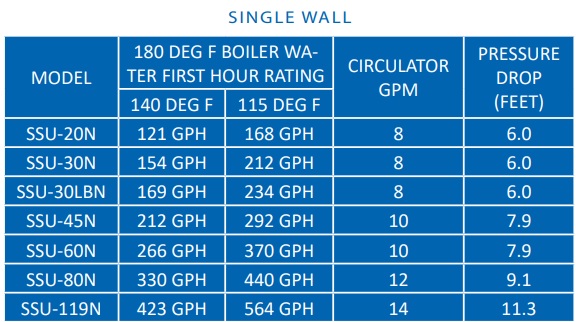

This can be tricky, but we will start by keeping it simple. Let's do the same thing as we did for sizing manifold pipes. Here is a spec sheet for an indirect water heater.

The spec sheet will give us the flow needed in the tank coil. The flow is 10 gpm. Looking at the above chart, we can use a 1" pipe. The tank tapings are ¾” and we need a larger pipe. Increase and reduce the pipe sizes right at the tank. The process involves moving 10 gallons of water through a larger pipe to a smaller tap, which increases the flow velocity through the tank coil. If you increase velocity, you increase thermal transfer. You would size the circulator to accommodate all the piping, fittings, and coil in the tank to achieve the proper flow.

I said it can get tricky; the information they supply on the spec sheet will be for a specific boiler size and first-hour rating. Since I always size the boiler for the heat loss and not the hot water demands, the boiler may be smaller.

Using the boiler size above, I may only get a 5-gallon-per-minute flow from the boiler instead of 10 gpm. Now the pipe can be ¾” with a bit larger circulator. Please note that this will lower the first-hour rating of the tank. I discussed this in a discussion on

Now that you have the proper pipe size to carry the BTUs needed for a zone of heat, you will have to size the circulator properly.

Disclaimer: The information found on this website is for informational purposes only. All preventive maintenance, service, and installations should be reviewed on a per-job basis. Any work performed on your heating system should be performed by qualified and experienced personnel only. Comfort-Calc or its personnel accepts no responsibility for improper information, application, damage to property, or bodily injury from applied information found on this website.