Ask Your Boiler and System Questions or Leave Your Comments Here

Multiple Steam Boilers

In large hot water systems, it has become a standard to use multiple boilers to better match the ever-changing loads of the building. This idea has not gained widespread adoption for steam systems, but its popularity is increasing. It is just as important for residential larger steam systems to use multiple boilers to achieve maximum fuel savings.

The boilers should still be sized properly according to the connected load, except for one warning: each boiler should be sized for 60% of the entire load. Measure all the radiation and convert to square Feet of steam (EDR). Divide that number by two. If more than two boilers are selected, do not size them for 60% of the load.

For example, 890 sq. ft. x .6 = 534 sq. ft. Choose the two boilers from that figure.

If more than two boilers are used, divide by the number of boilers.

Example 1280 / 3 = 427 sq ft each.

All main steam piping must be insulated. You cannot half-step into higher efficiency operation. Why install multiple boilers and have uninsulated mains, allowing the steam to prematurely convert back into condensate, which must then be reheated and converted back into steam?

While properly sizing the steam boiler remains the primary step to maximize fuel savings, installing multiple boilers is a secondary method to further increase comfort and reduce fuel costs.

When I say multiple boilers, it means more than one boiler, but in larger power burner steam boilers, you can get the burners configured as low/high/low. These boilers will operate in low fire, transition to high fire, and then drop back to low fire when the set-point pressure is reached. If needed, it will return to high fire and then back to low. This is all automatic. Boilers that can operate in low/high/low mode can effectively function as two boilers in one. Alternatively, two boilers with low/high/low modes are equivalent to four boilers when the loads are larger, or there are many varying-size zones. The idea is that when the system gets hot, the steam condenses more slowly in the insulated steam mains, and the low fire attempts to match the condensation rate more closely.

Another option would be full-modulating boilers. These could be purchased as power burners or atmospheric gas boilers. The operation would be the same as above, except with full modulation instead of just two inputs.

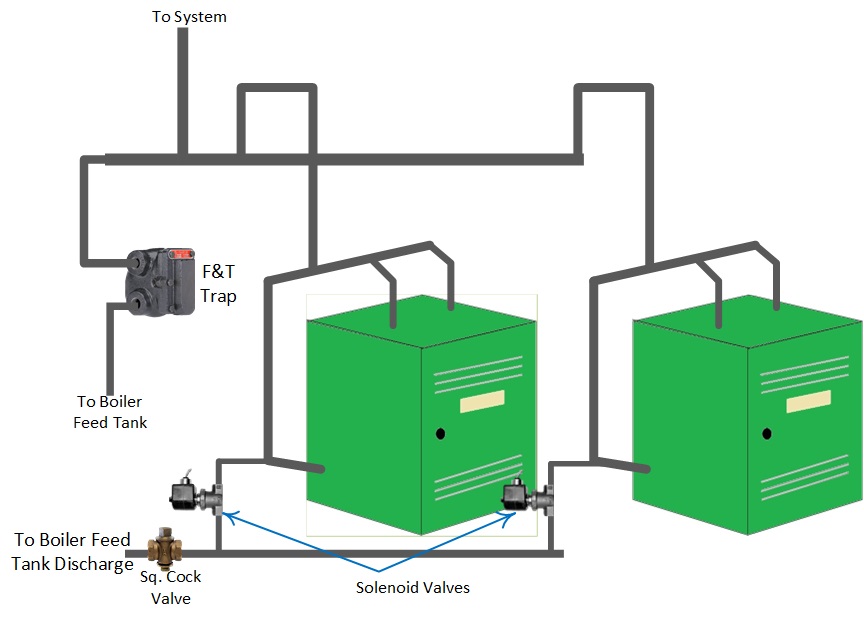

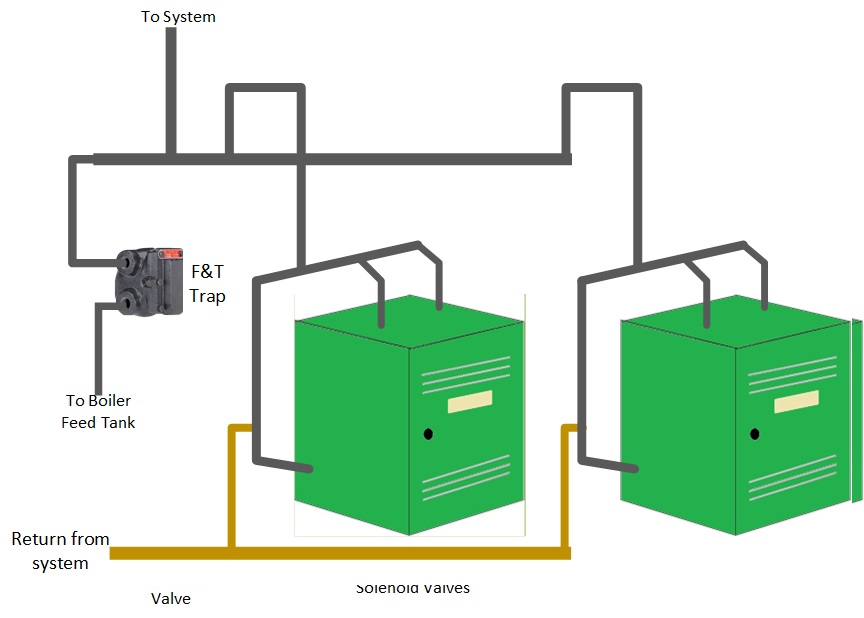

Return piping to multiple boilers

Drawings are incomplete for simplicity, see manufacturers drawings

Ignore the pipe sizes and dimensional data, as this drawing is for concept only. Your pipe diameters may be different. The boilers could be controlled by different means. The two most common applications would be extra pressure control mounted in the piping, set at different pressures, or staging controls that turn boilers on and off as needed, depending on pressure. There is one control manufacturer that looks at the pipe temperature at the end of the steam main.

Preferred Way - When doing multiple steam boilers, piping is also critical. We must use a dropped header and a a boiler feed tank, not condensate pumps. When using pumps, we do not use a Hartford Loop. Pipe into the return tee on the boiler. Each boiler must have a pump controller installed to start the pump, and a solenoid on the return line to the boiler that opens and closes as needed to supply makeup water. If two boilers are used instead of solenoid valves, a duplex pump can be used. This is one tank with two pumps. One pump can be piped to each of the two boilers.

Each boiler is piped as an independent unit, per the manufacturer's specifications, and the system riser from each boiler header extends above the common header and then down into the standard header. This will prevent condensate from one boiler from entering a non-operating boiler, thereby preventing flooding of the non-operating boiler.

It is also advisable to add a water level steam trap (not shown) to maintain a maximum water level in the boiler, which will drain into the boiler feed return tank.

Non-Preferred Way - Gravity return to each boiler, no pumps. While this is done many times without problems, I do not like to see it done. If you decide to pipe it this way, I would recommend using copper and oversizing the common return pipe by at least one pipe size. Also, increase each boiler return by one pipe size, also in copper. In this case, you do not need a steam trap to prevent the boiler from flooding. Water weight will push water out of a non-running boiler. When we pipe this way, we must pipe returns to the Hartford loop.