Steam Piping Tutorial

Ask Your Boiler and System Questions or Leave Your Comments Here

Drawings on this page are from my online or live seminar

Steam Boiler Tutorial

Most of your steam problems start when the customer wants a price on a new steam boiler. The larger number of steam boilers installed is oversized. This practice causes short cycling of the boiler, which reduces the efficiency and creates system problems.

The proper way to size a steam boiler is to measure the existing radiation. Convert all the radiation to square feet of steam, commonly referred to as EDR. Most of the time, do not add anything for piping or anything else. There are a few key points to consider. If the horizontal mains in the basement are not insulated, insulate them. (See chart for BTU loss of steel pipe). After sizing all the radiation, grab the manufacturer's brochure and select the boiler from the square feet of steam available.

Proper steam boiler operation starts with the near boiler piping. The piping of steam boilers has remained largely unchanged for approximately the last 100 years. The piping diagrams must be followed to the tee for a good operation. Always use an iron pipe above the water line of the boiler. Copper may be used below the water line if you choose. A few reasons we do not want copper above the water level, although it is not against national codes, are that the steam can leach the copper from the piping. These copper molecules can re-enter the boiler, causing a galvanic reaction. This will shorten the boiler's lifespan. Another reason is that copper pipes expand far more than black iron pipes. This will stress the joints more than screw- or welded-pipe joints. All the piping around the boiler has names. Let's get familiar with these terms.

Important Measurements

More Information

US Boiler MegaSteam Drawing

Another Idea - Dropped Header

Now see what not to do

Disclaimer: The information found on this website is for informational purposes only. All preventive maintenance, service, and installations should be reviewed on a per-job basis. Any work on your heating system should be performed only by qualified, experienced personnel. Comfort-Calc or its personnel accepts no responsibility for improper information, application, damage to property, or bodily injury from applied information found on this website, as it should be reviewed by a professional.

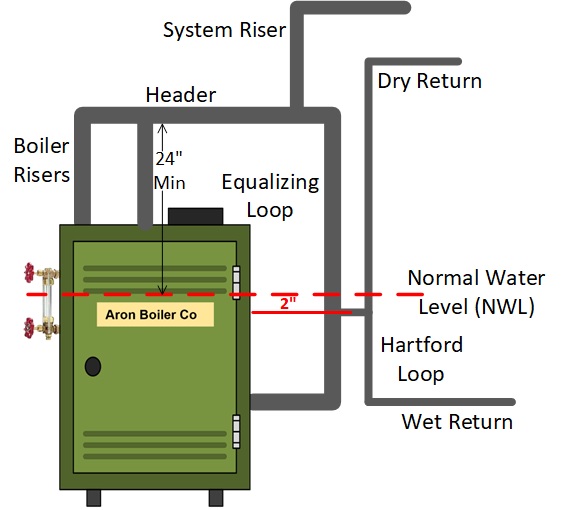

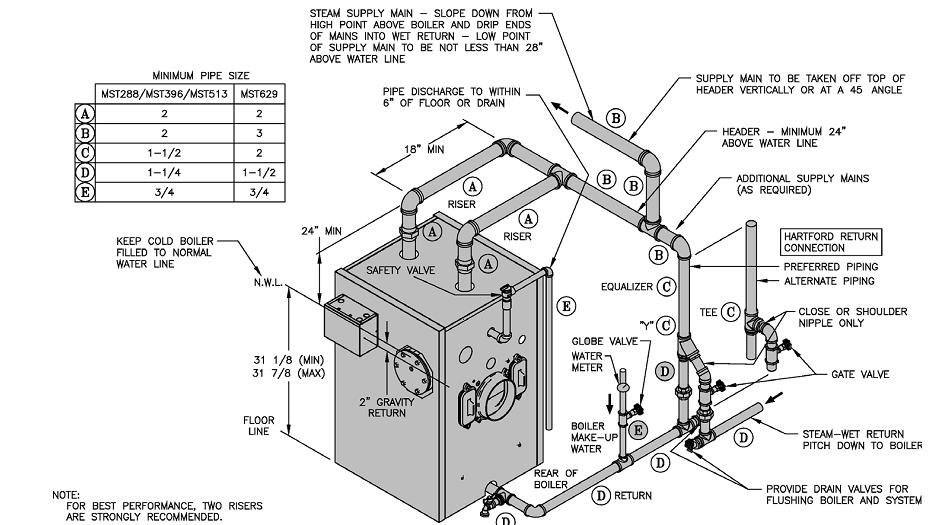

Riser to Main System

The system riser, as it is normally called, carries the steam from the header to the system. The steam at this point should be dry and moving quickly. If there is more than one main system, there should be multiple system risers. In other words, a system riser for each system main.

Click the BACK button

Boiler Riser

The boiler riser(s) carry the steam produced in the boiler to the header. There may be one riser or multiple risers. If using multiple risers, they should all connect to the header before any system risers are connected to the boiler header. Refer to the manufacturer's installation manuals for the number of risers and manifold pipe sizes.

Click the browser BACK button

Header

The boiler header is part of the heart of the near boiler piping. The purpose of the header is to collect all the steam from the boiler, which includes some water, and move it to the system risers, allowing the water to separate from the steam before entering the system risers. The steam will rise in the pipe, while the water will remain at the bottom. As the steam reaches the system risers, it will rise, leaving water and a small amount of steam in the header. This will help produce dry steam.

Click the browser BACK button

Equalizer

The equalizer does exactly what it says. It will equalize the pressure between the header, the supply side of the boiler, and the return side of the boiler. As the header builds steam pressure, most of the steam goes out through the system risers. The balance pushes into the equalizer. The equalizer has a water volume equal to the water level in the boiler. The steam pressure pushes down on the water in the equalizer. If there is one lb. of pressure in the boiler and header, there is one lb. of pressure pushing down on the water in the equalizer. This creates equal pressure on the boiler's supply and return. When the supply and return pressures are equal, the water will remain in the boiler.

Click the BACK button

Normal Water Line

This is more commonly known as the Normal Water Level (NWL). This is where the boiler manufacturer would like to see the boiler water maintained for the best operation. The manufacturer will always specify this dimension from the bottom of the boiler jacket or the floor to the desired NWL. Pay attention to this as you are piping the boiler.

Many steam boilers are equipped with automatic water feeders. The thought is that we no longer have to check the water level. This is incorrect. The automatic water feeder does not maintain the NWL. It maintains the water level just above the probe. The automatic water feeder is for emergency use only. It will add water as needed to maintain a minimum water level if you are not home or have recently forgotten to check the water level. You should check and maintain the water level at the manufacturer's suggested NWL location.

Click the BACK buttare equipped with automatic water feederson

Condensate Return

The condensate return is the pipes that carry the condensate, steam, which condensed back into water, back to the boiler. There are two types of condensate return pipes. They are known as DRY returns and WET returns. The only difference is the location of the pipes. If the return pipe is above the water line, it is called a dry return. If the condensate return pipe is below the water line, it is a wet return. The wet return, submerged below the water level at all times, becomes clogged with debris over many years. These wet returns are often referred to as the "garbage dump" of the system. It is a good idea to replace them when a new steam boiler is installed in a residential application. I have found that replacing about 10 feet of wet return can help you bypass most of the debris in it. Dry returns will not typically be a problem due to blockage.

Click the browser BACK button

Hartford Loop

The Hartford loop was first designed as boiler protection, so if the wet return would spring a leak, all the water would not drain out of the boiler and cause a dry fire. Dry firing the boiler means there is no water in the boiler, and the boiler continues to fire. This will crack the boiler and require a boiler replacement. Never add water to a dry fire condition unless the boiler has had ample time to cool down. Adding water to a very hot steam boiler can cause physical injury, damage to the cast-iron boiler sections, and/or property damage. A Hartford loop should be installed on all steam boilers unless the boiler has a pumped return from a condensate pump or boiler feed tank. Never install check valves in the return lines of residential steam boilers with dry or wet returns.

Click the BACK button

2" Distance on Hartford Loop

The 2" distance shown on the drawing for the Hartford loop is critical. This is the distance from the normal water level (NWL) to the bottom of the elbow on the Hartford loop. Follow the manufacturer's instructions in the Installation and Operation (I&O) manual. If in doubt, use the center of the elbow. If this horizontal distance becomes too high or too low, it can affect performance or create noise. The horizontal piping from the tee or wye to the Hartford loop should be as close as possible to minimize the distance. If that connection becomes too long, it could also cause water hammer noises in the Hartford loop.

24" Distance

The 24" distance shown in the drawing is the distance from the normal water line (NWL) to the centerline of the header. This is a minimum distance. The higher the header, the better. Our concern is to make the steam as dry as possible. Longer pipes from the boiler to the header will allow more water to separate from the steam as it travels up the boiler riser.

Click the browser BACK button

US Boiler Negasteam Manufacturer Spec's

Click browser back button to retun

Dropped Header

Dropped headers may be used when the installation will have low ceilings, or anytime you want drier steam. The boiler risers will go up the required minimum 24" distance; there is no maximum distance, and the elbow will be horizontal and then back down. The more piping and fittings the steam passes through, the drier it becomes.

Click the BACK button