What is Outdoor Reset? (ODR)

How Does ODR Work?

1. Heat Loss - Perform a Manual-J room-to-room (new or retrofit installation) or envelope (if a retrofit boiler) heat loss.

2. Measure the Radiation - This is the only time you need to measure radiation on hot water boilers. DO NOT SIZE THE BOILER FROM THE AMOUNT OF RADIATION or MATCH THE OLD BOILER SIZE! Measuring radiation has nothing at all to do with the size of the new boiler. If you size the boiler based on the amount of radiation in the home, it will be oversized or grossly oversized most of the time. Oversizing the boiler will always result in wasted fuel. The boiler will short-cycle, reducing its efficiency. If you install a high-efficiency boiler that is oversized, you will lose the most efficient part of its operation, as the minimum fire will not drop low enough. See Don"t Oversize HE boilers under the High Efficiency Boiler Tab

3. Boiler design temperature - maximum boiler temperature required to heat the home at the lowest outdoor air temperature.

4. Boiler start temperature

5. Outdoor Start Temperature

6. Outdoor design temperature

7. Boiler minimum temperature

8. Differential required

9. Boiler delay

10. Warm Weather Shut Down temperature

Note: Not all ODR controls will have all the parameters listed above.

Let's determine how to gather the above information

2. Measure the amount of radiation. You will need to calculate the heat output from your system. Measure only the element of the copper tube baseboard, not all the piping within the cover. Measure all the cabinet convector's width, depth, and height. Determine the sq. ft. of cast iron radiation. When you have this information, charts are available in our CHARTS & GRAPHS tab to help you calculate the water temperature required for your system. We can also assist with this if you purchase a PREMIUM heat loss. That will provide the BTU output per square foot of radiation. We then use another set of charts to calculate water temperature.

2a. Hydro air systems the minimum water temperature should be 130F to 135F and the maximum will normally be about 160f - 180f.

2b. If the system is a coppertube baseboard, I would normally suggest a minimum water temperature of 120F and a maximum of 160F - 180F

2c. Cast iron radiation systems the minimum should be 100f to 110f and a maximum of 160f.

2d. All the above water temperatures are general settings. Actual and additional fuel savings depend on the building's heat loss and the amount of radiation in the system.

3. Boiler design temperature varies by boiler build. You have cast-iron equipment, which requires a warmer water temperature or less flow due to condensing boilers, unless you have a mod/con boiler, which is designed to condense. The lower the water temperature required for your system, the better choice is the newer mod/con boilers because the cooler the water temperature, the more efficient the boiler operates.

4. The boiler start temperature will normally be the same as the thermostat setting, although it may not be. This sets the bottom parameter for the heating curve.

5. The outdoor start temperature will normally be set the same as the thermostat setting. This is the outdoor air temperature at which the heating curve begins. This is normally the same as the building temperature.

6. The outdoor design temperature is the temperature we used to calculate the heat loss. We use the ASHRAE design temperature recommendations for your area. The outdoor design temperature is the average coldest outdoor temperature for your area.

7. Boiler design temperature is the highest water temperature you want to see in the system at the coldest outside temperature. This setting is dependent on the amount and type of radiation, as well as your heat loss.

8. The differential above and below may be adjustable, while others are preset. If the differential is adjustable above and below, I like this the best because we may not want them both the same.

9. Boiler delay is how long the control will wait until the second boiler is started. This is normally adjustable from 30 seconds to 4 minutes or more, depending on the manufacturer. Not all outdoor reset controls have this option.

10. Warm weather shutdown (WWSD) is an option, which is nice for commercial buildings and apartments. It will turn the boiler(s) off when the outdoor air temperature exceeds this setting. If the thermostat requests heat, the boiler will ignore it. It is usually set between 65F and 68F. If the thermostat is set at 70º, the WWSD is 68F, and the outside air temperature is 71º, the boiler(s) will not turn on. Not all outdoor reset controls have this option.

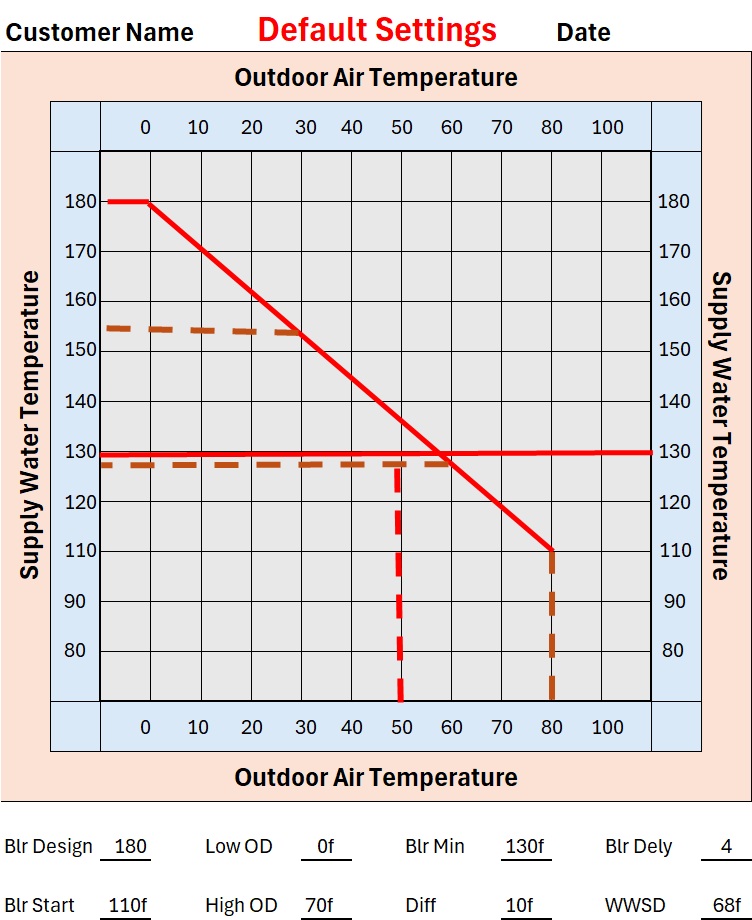

Now that we have the information from above, we can set the functions in the outdoor reset control and use a reset curve. The following reset curve is set to the example listed below. We calculated all the necessary information and arrived at these values.

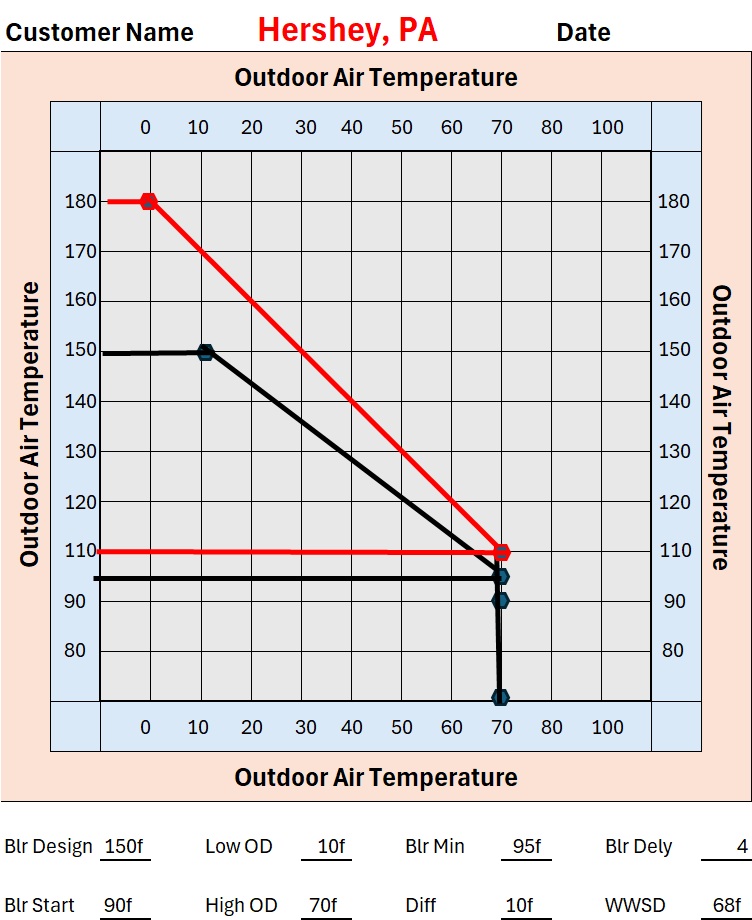

Changing the ODR parameters in Hershey PA

The building used to have a gravity hot-water system decades ago, with 1,600 sq. ft. of cast-iron radiators split into 4 zones. With a heat loss of 144,235 and 1600 sq ft of radiation, we need to do some simple math. Heat loss of 144,235/1600 sq. ft. of cast iron radiation = 90 BTUs per square foot of radiation. We calculated the water temperature from this chart. Find the heat loss per sq. ft. of radiation (90) and go up to determine the water temperature.

We also have charts for older (standard) copper tube baseboard.

After doing this calculation, we removed the old boiler, reduced the boiler size from 225k to 160 BTUs to match the new heat loss. We used two 80,000 BTU New Yorker oil-fired boilers and a Taco SR503-EXP multi-zone relay, including a Taco PC-702 outdoor reset control.

These were the default parameter settings on the control

Look at a scernerio from Hershey PA.

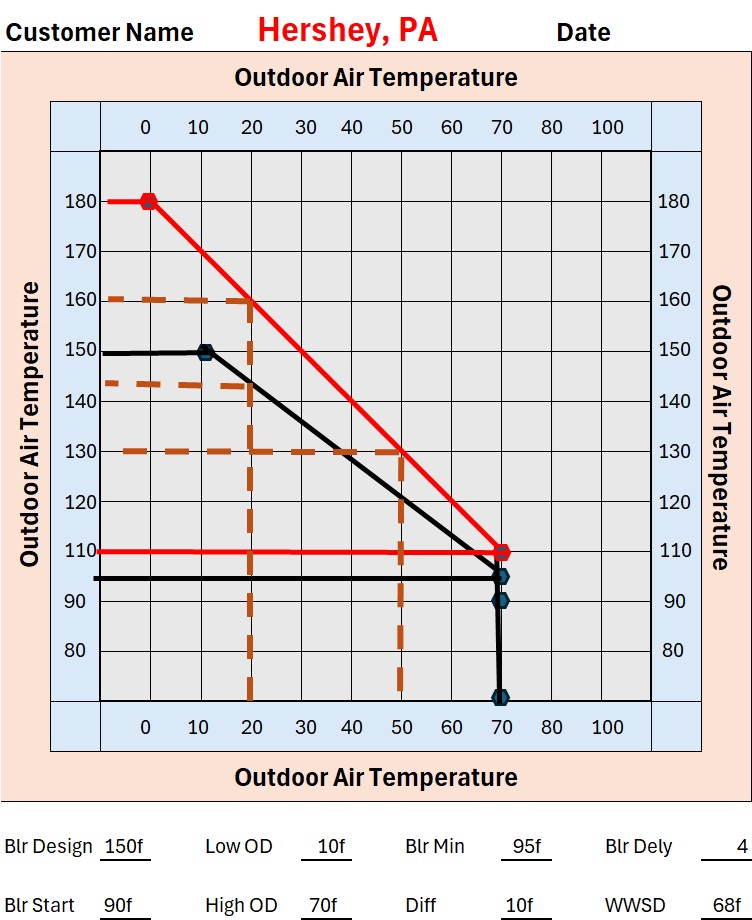

This is how we plotted the heating curve to set our control. You will see from the example that the water temperature at 70F outdoor air temperature is 95F. If the outdoor air temperature drops to 10F, the system water temperature will be 140F. While this is a good temperature, it is not a bad idea to increase it 5-10 degrees. The outdoor air temperatures and water temperatures can all be changed to fit any scenario.

If the temperature today were 25F, the reset control would use a target temperature of about 123F for the system supply water temperature. If you raised the water temperature on the left and redrawn the line to the new maximum temperature, the water temperature would increase. The lower the water temperature setting, the more fuel is saved. I must repeat myself here and remind you to be careful of lower water settings with cast iron boilers without the proper boiler protection

Let's take a look at the outdoor curve from the way it was shipped (factory default) and what system water temps we would have been operating at. On a 20-degree day, you can see that the system water temperature is almost 30 degrees cooler. This will use less fuel. We need to calculate the heating curves by doing the heat losses and measuring the radiation, and readjust the curves for each job as explained above.

You can print a Blank ODR Worksheet and play with changing outdoor air temps and water temps. If this issue occurs in your own home, you can adjust the settings and fine-tune your system.

Caution - If you want to make your own blank chart, the blocks must be squares, not rectangles for accuracy

Disclaimer: The information found on this The website is for informational purposes only. All preventive maintenance, service, and installations should be reviewed on a per-job basis. Any work performed Maintenance of your heating system should be performed only by qualified, experienced personnel. Comfort-Calc or its personnel accepts no responsibility for improper information, application, damage to property, or bodily injury from applied information found on this website, as it should be reviewed by a professional.