Most commonanlly asked questions about steam boilers & steam systems

All drawings are conceptual drawings and may be incomplete. More specific drawings may be required for your application.

When a steam boiler is replaced, should it be sized by a heat loss or by measuring the radiation?

Steam boilers, unlike hot water boilers, should never be sized by a heat loss unless you are going to change the size of the radiation. Changing the radiator size is not a common practice due to the associated cost. To size the steam boiler, measure the height of the radiator from the floor to the top, count the number of columns or tubes, and count the number of cast iron sections to make up the length of the radiator. All the radiators will have to be converted to sq. ft. of steam. Once you have calculated the square footage of steam for all radiators, add them together. This is the total square footage of steam required to heat the radiation. Refer to the boiler brochure and match the square footage of radiation to the boiler's square footage rating in the manufacturer's literature. Never add anything to the total square feet measurement of the radiation for piping. The manufacturer already deducted 33% of the square feet of steam available for system piping losses.

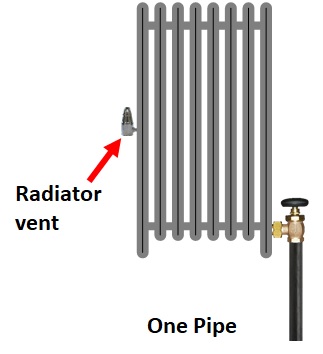

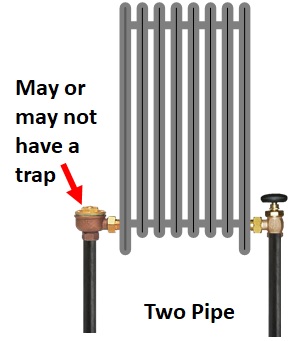

What's the difference between a one pipe and two pipe steam system?

One Pipe Steam System

Two Pipe Steam System

I've been told to drain the boiler over the summer or flush the boiler every summer. Is this correct?

No! You should never completely drain or flush the boiler annually. This would only be done when a service requires draining. Every time you add water to the boiler, you introduce oxygen, minerals, and chemicals, along with the water, which will shorten the boiler's life.

I have a one-pipe steam system, and some of my radiator shut-off valves are wide open, and some are partially open. Is this OK?

No, all radiator shut-off valves in a one pipe steam system should be closed all the way or wide open. Do not have the valve partially open.

What is the difference between a wet return and a dry return?

The return piping is the pipe that carries the condensate back to the boiler from the system. The location of the piping determines if it is a wet return. If you look at the steam boiler, you will see a sight glass that indicates the water level in the boiler. All the system piping below that water level will also contain water. We refer to the return piping located below the water level as a wet return, as it is filled with water. Any return piping above the water level is called a dry return, as it is not full of water all the time.

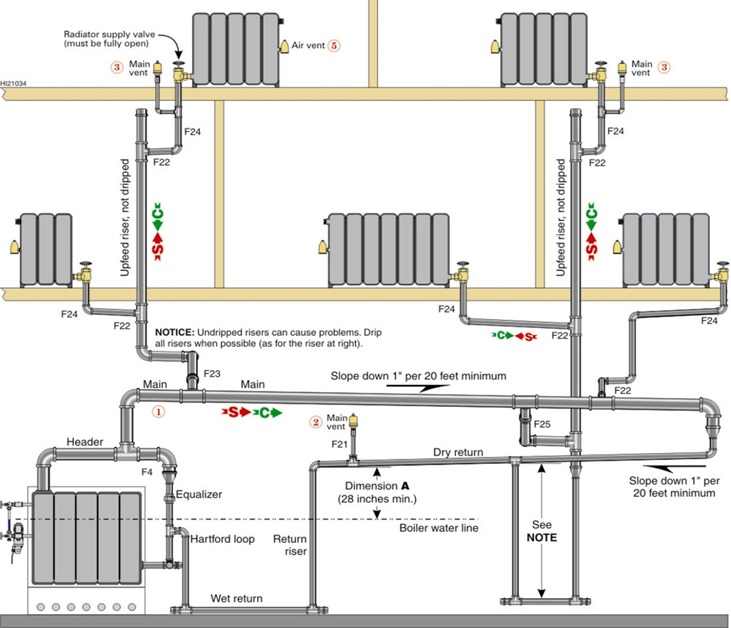

One Pipe Dry Return

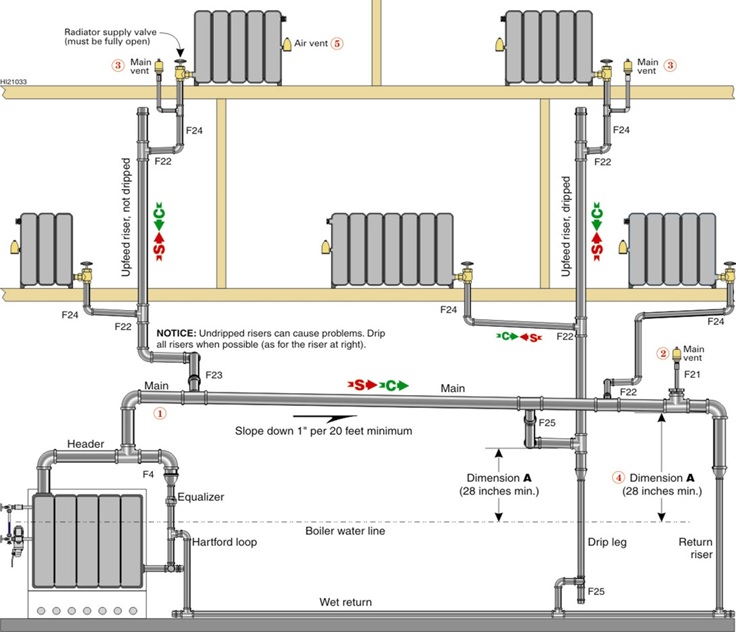

Two pipe wet return

I heard a lot of terms for steam boiler near boiler piping. What are they?

Below is a drawing of near boiler piping and a list of names and functions.

Boiler Riser(s) - Delivers the steam from the boiler to the boiler header. There may be more than one boiler riser.

Boiler Header - Collects all the steam from one or multiple boiler risers.

System Riser - Delivers the steam from the boiler header to the system piping.

Equalizer - Equalizes the pressure between the top and the bottom of the boiler.

Hartford Loop - Was invented before Low Water Cut-off controls. If the return were to leak, all the water would not drain out of the boiler. The boiler would still have water up the Hartford loop tee. The Hartford loop would be installed 2" below the normal water level(NWL).

Condensate Return - Return water back to the boiler from the system as the steam condenses.

What is the purpose of a Hartford loop?

A Hartford loop was first designed to avoid all the water draining out of the boiler if a leak occurred in the wet return line. The old systems, long before low-water cut-offs were invented, were piped at floor level and directly into the boiler. If a leak occurred, the water would completely drain from the boiler, and the coal fire would continue to burn. The cast-iron boiler sections began to overheat, resulting in a lack of heat in the building. Someone would go to the basement to add water. The cold water hit the overheated iron, and an explosion ensued. The Hartford loop will pipe from the boiler end of the wet return and go vertical to 2" below the normal water level. If there is a wet return leak, the water would only drain as low as the Hartford loop, leaving a substantial amount of water in the boiler.

What is the purpose of an equalizing loop?

An equalizer or equalizing loop is to have the same pressure on the supply side of the boiler as the return side of the boiler. As pressure builds on the supply side of the boiler, it is transmitted through the header, with some of the pressure going to the system and the remainder being directed into the equalizer. In the equalizer, there is water as high as the water level in the boiler. The pressure pushes the water down. With the same pressure on the supply as the return sides of the boiler, the water stays in the boiler.

What is meant by an "A" dimension?

The "A" dimension is factored in when we have a one pipe steam system and is the vertical distance from the Normal Water Level (NWL) listed by the manufacturer to the lowest horizontal carrying steam main. The steam main will run around the basement, and all your radiation will be piped off the steam main. Normally, the "A" dimension should be 28" minimum. This 28" measurement is important for getting return water back into the boiler and avoiding a noisy operation. It is important to note that 28" of water in a vertical pipe equals one psi. When measuring the "A" dimension, measure down from the ceiling, not up from the floor. The ceiling will be more level than the basement floor in most cases.

The boiler will typically operate at no more than two psi. Some boilers operate at ounces of pressure, but the majority operate at pounds of pressure. If the boiler is operating at 1.5 pounds, which means there is 1.5 pounds of pressure on both the supply and return sides of the boiler, the water from the system will not enter the boiler. The water in the wet return must exceed the pressure in the boiler to allow the return condensate to enter the boiler. This is where the importance of the "A" dimension comes in. Remember the "A" dimension is the vertical distance from the NWL to the lowest point of the horizontal steam carrying main. This is usually the other end of the basement. The wet return will run around the basement and turn up to connect to the steam main. The "A" dimension will occur in the vertical pipe connecting the wet return to the steam main. When the boiler is not running, the water level in the vertical pipe should match the level in the boiler. When we build steam, the steam in the radiation and the steam main will condense back into water. It will run along the main and collect in the vertical pipe at the end of the steam main. As the water stacks, it will increase the pressure in the return due to water weight.

What is a "B" dimension?

The "B" dimension is like the "A" dimension except it is used when we have two pipe steam systems. The "B" dimension is also calculated differently. We are still interested in the distance from the NWL to the lowest steam-carrying main. Instead of 28", it's now 30" per pound of steam in a system. If the system were operating on two psi, we would need to have a vertical distance from the NWL to the lowest point on the steam carrying main of 60" or 5'. Since most basements do not allow that kind of height, we use traps with gravity return or pumped returns.

How important is venting a steam system?

Steam system efficiency is affected by venting. All the vents must work. On a one-pipe steam system, you should have a main line steam vent about 6" from the end of the steam main. The vent should not be located at the very end of the main. The purpose of a main line steam vent is to vent the main as rapidly as possible. This will help balance the steam system. The idea of a main steam vent is to get steam to the end of the main as quickly as possible. This may require more than one main steam vent. After the steam gets to the end of the main, the vent closes, and the radiator vents now have to vent the radiator and vertical piping. Any radiator larger than 25 to 30 square feet should have two automatic air vents installed. The slower the system vents, the slower the system heats. Good operating vents save fuel dollars.

What is the purpose of a main line vent?

The main line vent is to vent the main piping on a one pipe system (one pipe to the radiator). It is important for fuel efficiency and even heating of the steam system. The main line vent must vent the main rapidly to allow the radiator vents to vent the radiators evenly. If all the air is removed from the main piping and the radiator vent only needs to vent the vertical piping and the radiator, it is easier to balance the system. I have installed two or even three main-line vents on a single main.

When I have a one pipe steam boiler replaced, should the main line vents be replaced, and where should they be located?

Absolutely, the main line vent must work well for an efficient steam system. It is wise to add more than one if the main pipe is venting poorly. They should be a minimum of 12"-15" from the end of the main, never in a tee at the end of the main. The vent could even be placed after the last riser to the last radiator off the horizontal main.

My radiator's air vents are only halfway up the radiator. Is this correct?

Yes, the air vent should be located halfway up the steam radiator. The vent on a hot water radiator should be at the top. Since the steam vent closes when steam enters, it would not vent as much air if it were located at the top. When steam enters a radiator, it tends to rise to the top immediately, thus closing the valve prematurely.

I have a few air vents that will release steam during the boiler operation. Is this normal?

No, the air vent is supposed to close when steam hits the vent. If the vent is venting steam, you are losing water from the boiler. This would mean that when you need to add more water, you are adding oxygen, minerals, and chemicals, all of which are detrimental to the boiler and steam system. The more water you add to the boiler, the shorter its life expectancy will be.

I am a firm believer that all the vents should be replaced at the time of the installation. I realize it is expensive, but it does make the system work more efficiently. The vent on a steam radiator should be about 1/2 the distance from the top to the bottom of the radiator. I would double-vent that radiator if the radiator is larger than 25-30 sq ft of steam. The second vent should be lower than the original vent. You may hear a radiator vent hissing somewhat, but not really loudly. If you can hear it 5 or 6 feet away, I would wonder if the main line vent is working properly or is large enough.

If the venting isn't good, can that cause a problem long term?

Yes, when your boiler is boiling the water, this creates carbon dioxide gas. If this does not escape the system as quickly as possible and mixes with condensate, it will form carbonic acid. The acid creates condensate grooving in rerun lines, and you will also see deterioration at the treaded end of wet return lines when disassembled. All air vents must function properly and be sized correctly.

Does the main horizontal steam line need to be insulated?

The entire horizontal steam main should be insulated. We need to keep the steam in a steam state as long as possible. Many years ago, homeowners removed asbestos insulation from the steam main due to health concerns, and others removed partial insulation to provide heat to certain areas of the basement. We need to insulate all of the main steam pipes, and it is also a good practice to insulate the near-boiler piping and the takeoffs up to the floors. I also believe we should insulate all steam lines in unconditioned spaces, as well as around the boiler.

We pay to create steam. We must keep it in a vapor state as long as possible. The steam must go up to the radiators to heat the home. If the steam main is not insulated, the black pipe gives off the heat generated by the steam. At first, this may not sound like a bad idea, but upon closer examination, it becomes apparent that it's not. We create steam, which then leaves the boiler and enters the steam main. If there is no insulation, the piping emits approximately 212 BTUs per foot of 2-inch black pipe. The steam cools down and condenses into water. The condensate works its way back into the boiler. We must reheat the water to 212F. We then have to change state from a liquid back into a vapor. It takes 970 BTUs to convert 212°F water to steam at 212°F. That is about 5 times more energy than it would take to heat water from 32°F to 212°F. Someone has had the main pipe insulation removed to heat a certain part of the basement. All this steam is condensing back into water, which needs to be brought back to 212°F, and then converted back into steam. Insulate those pipes and keep the steam as a vapor for as long as possible.

Another problem that can happen with removing pipe insulation from steam mains is a condition we call water hammer. This sounds as if someone is beating the pipes with a hammer. It occurs when there is too much water in the horizontal mains and steam glides across it. Insulate those horizontal main steam pipes for fuel savings and quieter operation.

How important is insulation on the steam pipes in the basement?

2. A steam main with no insulation, the steam produced will condense back into water quickly

3. This increases operation costs $$$

4. More condensate in steam mains will increase the chances of increasing system noises (water hammer)

5. Creates slower heating due to steam collapsing to condensate

6. Makes balancing a one pipe steam system very hard

There's a lot of talk about steam going to condensate. What adverse effects does this have? When the boiler receives a demand for heat, it must raise the water temperature from its current level to 212F. But, you do not have steam yet; you have 212F hot water. To change the state from 212F water to 212F steam, the boiler must add 340 BTUs per pound of water. To put this into perspective, that would be 5 times the amount of fuel it would take to raise water temperature from 32°F to 212F.

If I should not remove pipe insulation, how should I heat that basement?

Heat the room with condensate or boiler water. Have the contractor add a section of baseboard in the area you want heated. He can install it on a thermostat, allowing you to use it as needed or maintain a consistent room temperature. This will cost more money to install, but you have control over the process. It will also operate much cheaply than removing insulation. Basement areas are easy to heat as they are typically located below grade. This drawing illustrates the process of generating heat and hot water by the boiler.

How does a two pipe system vent?

A two-pipe steam system uses traps that open when cooler and close when steam hits them. The air in the radiators is vented very rapidly right through the radiator trap. There is normally a larger trap at the end of the main to vent the main and a large vent on a dry return or an open pipe at the condensate pump.

How do you balance a one pipe steam system?

Many people believe a one pipe steam system is balanced by adjusting the vents on the radiators closest to the boiler vent slower than the vents on the further radiators from the boiler. This could not be further from the truth. The location in the system has very little to do with the system's balance. The radiator size does the balancing. First, verify that the main has good venting. Next, adjust the larger radiators to vent faster than the smaller radiators. This makes more sense as the larger radiators have more air to vent. Remember, if the radiator is too large, usually larger than 30 EDR, double venting may be required.

Yes, even though the boiler water looks clean enough to drink, we are not concerned with how clear the water is. We are concerned with oils that have been added to the water during manufacturing, such as pipe oil and flux. The oil floats on top of the oil and must be removed. This requires skimming.

Why is the water level in the gauge glass bouncing a lot and even disappearing at times?

This is called surging. After the installation of a steam boiler, a significant amount of oil will be present in the water, which can be attributed to the manufacturing of the boiler, pipes, and the installation process. This will cause a surge of water, resulting in a violent bouncing of the water as it steams. This causes the water to leave the boiler through the supply taps. This is resolved by skimming the boiler. Skimming will remove the oil from the surface of the water. The oil is lighter than the water, so it floats on top of the water. The steam has a difficult time breaking through the oil, but when it does, it leaves at a rapid speed. The velocity increases as it finds the supply tapping and heads up the pipe. This creates a suction and pulls boiler water up with it. Some water flows to the header, and a significant amount falls back into the boiler, causing the water level to fluctuate. Usually, what you see in the gauge glass is not as bad as what is happening in the boiler.

Skimming is getting the water almost steaming rather than draining the surface of the water off to a bucket. A small amount of water will need to be added back in while skimming. Do not skim too fast. I suggest the skim stream on a residential product to be no larger than a wooden pencil. The slower the better. Typically, this does not require the use of any chemicals. If the use of chemicals is necessary, follow the manufacturer's recommendations.

The water glass on the side of the boiler has two valves; should they both be open?

Yes, they both need to be all the way open to see the water level as it changes. It is a good idea to verify that both taps are clear of debris, as they will occasionally block. The level of the water should always be kept at the normal water level (NWL) suggested by the manufacturer.

I have an automatic water feeder on my steam boiler. Do I still need to check the water level?

Do the newer electronic low water cut-offs need to be maintained as the old float type did?

They do not require draining as the older float type did. The older float type required water to be drained from them approximately every two weeks to maintain a clean float chamber. This verified that the float would be able to move and shut down the boiler if the water level dropped too much. The water should be drained until it runs clear. Do not drain any more water than needed. The newer electronic probe type still requires annual maintenance. They should be pulled out every year, and the probe, the part that is submerged in the boiler water, should be cleaned, reinstalled, and tested.

What should the pressure be on my steam boiler?

Most residential cast iron radiator systems will be operated at a cut-out pressure of 2 psi and a cut-in pressure of 0.5 psi. This means the boiler will run until it reaches the cut-out pressure of 2 psi, at which point the burners will shut down. As the steam condenses, the pressure in the system drops to the cut-in pressure of 0.5 psi, and the burners will fire back up. When adjusting steam pressure, you must check the control. Some of the differential pressures are added differentials, and others are subtractive differentials.

It is becoming more common today to work with lower pressures. Some systems will work on ounces of pressure. The higher the pressure, the more fuel it takes. Residential systems with cast-iron radiators should never need to be operated above two psi. The higher the pressure, the greater the fuel bill. The fuel bill will grow exponentially. If more pressure is required to heat the radiators, check the venting.

I hear you should always replace wet returns when the steam boiler is replaced. Why?

The wet return is always full of water to the height of the water level in the boiler, so there is a lot of rust buildup. This slows down the returning condensate to the boiler. If the boiler has an automatic water feeder, it could cause the boiler to overfill. When the old boiler is disconnected, have the installing contractor check the return lines. If the water cannot return to the boiler within the proper timeframe, the auto feeder will add more water, potentially causing the boiler to flood. This could also result in water backing up into the horizontal mains, causing water hammer. The worst-case scenario is the water backs up into the system and leaks out of your radiator vents and onto your beautiful floor.

If you do not have an automatic water feeder, the boiler will shut down on a low water condition. As the water slowly works its way back to the boiler through all the rust in the return piping, it will come back on. This will create very uneven heating.

What about dry returns? Do they need to be replaced with the boiler?

Normally not. They are not full of water and are normally spotless, many years after they were originally installed. They do not need to be insulated.

I have heard that steam systems are supposed to be noisy. Is that true?

No, steam systems should be quiet. The pounding noise is called water hammer, which is normally caused by steam finding puddled water in a horizontal pipe. This can be remedied. It just takes proper near boiler piping to get dry steam (98% dry), insulation on all the basement steam carrying mains, proper use of pipe hangers to avoid sagging mains, and proper near boiler piping.

I hear the term dry steam. What does that mean and why is it important?

Dry steam means that most of the excess moisture has been removed by the steam. This happens when the steam goes vertical out of the boiler at least 24" to drop out the heavy moisture. As the steam travels through the near boiler piping elbows and piping, it removes as much moisture as possible.

What is the importance of dry steam?

When we talk about dry steam it usually is 98+% dry. We have removed most of the excess moisture. Dry steam moves much faster in the system than wet steam. Wet steam also releases its latent heat quickly, which means it turns back into condensate sooner. This will cost you more to reheat it and turn it back into steam again. Wet steam uses more fuel to heat the home, takes longer to satisfy the thermostat, causes water hammer (noises) in the system, and causes the boiler to short-cycle.

Can I connect an indirect water heater to my steam boiler?

Yes, although this is simpler on newer equipment than older equipment. Most manufacturers offer the tapings for the indirect water heater supply and control. The tank return will normally return to the boiler return taping. I would suggest the contractor follow the manufacturer's instructions when this is done. Their installation manual typically provides instructions on how to perform this task. Here is a general piping diagram showing baseboard and an Indirect water heater

The control would utilize the taping "L" and the indirect supply pipe would utilize the taping.